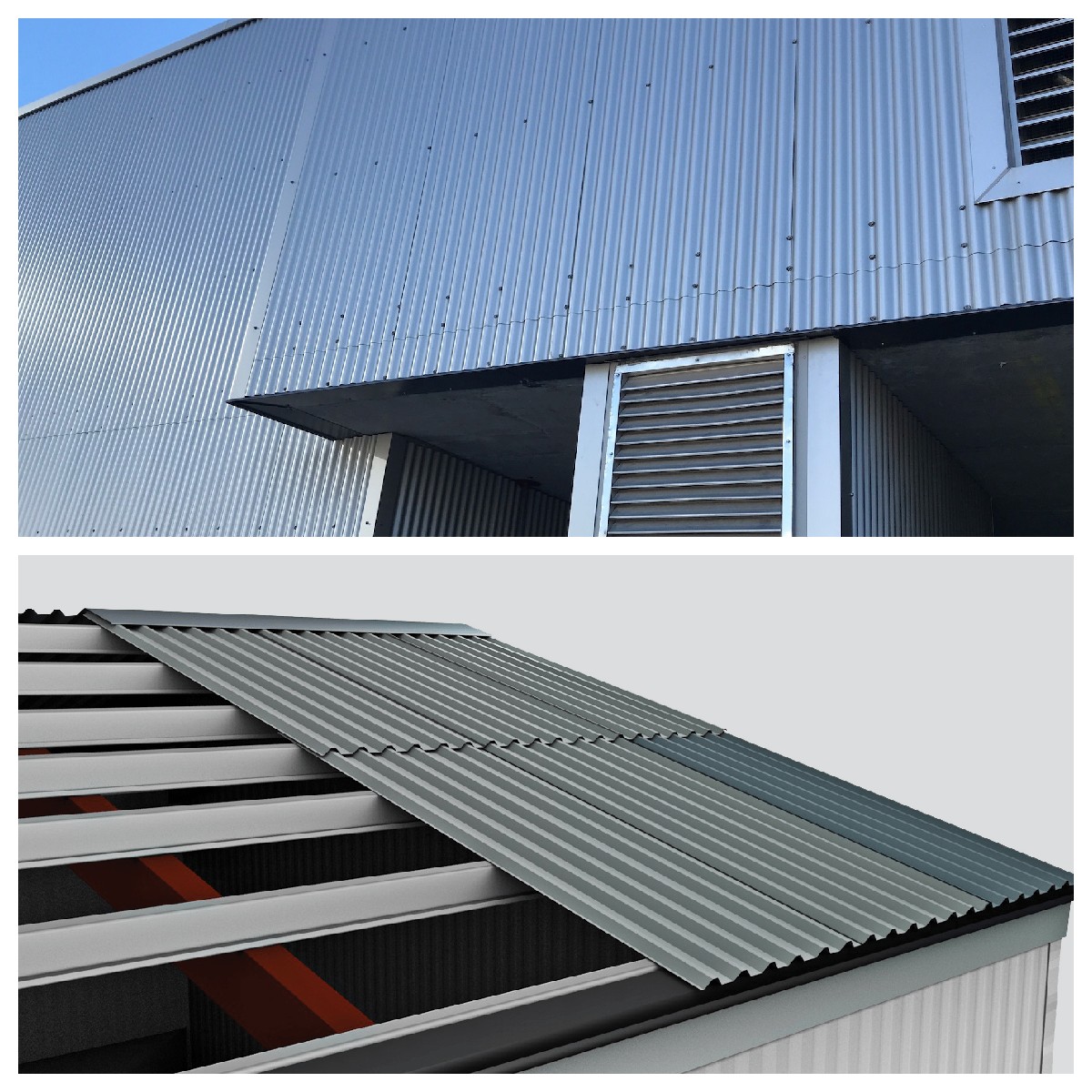

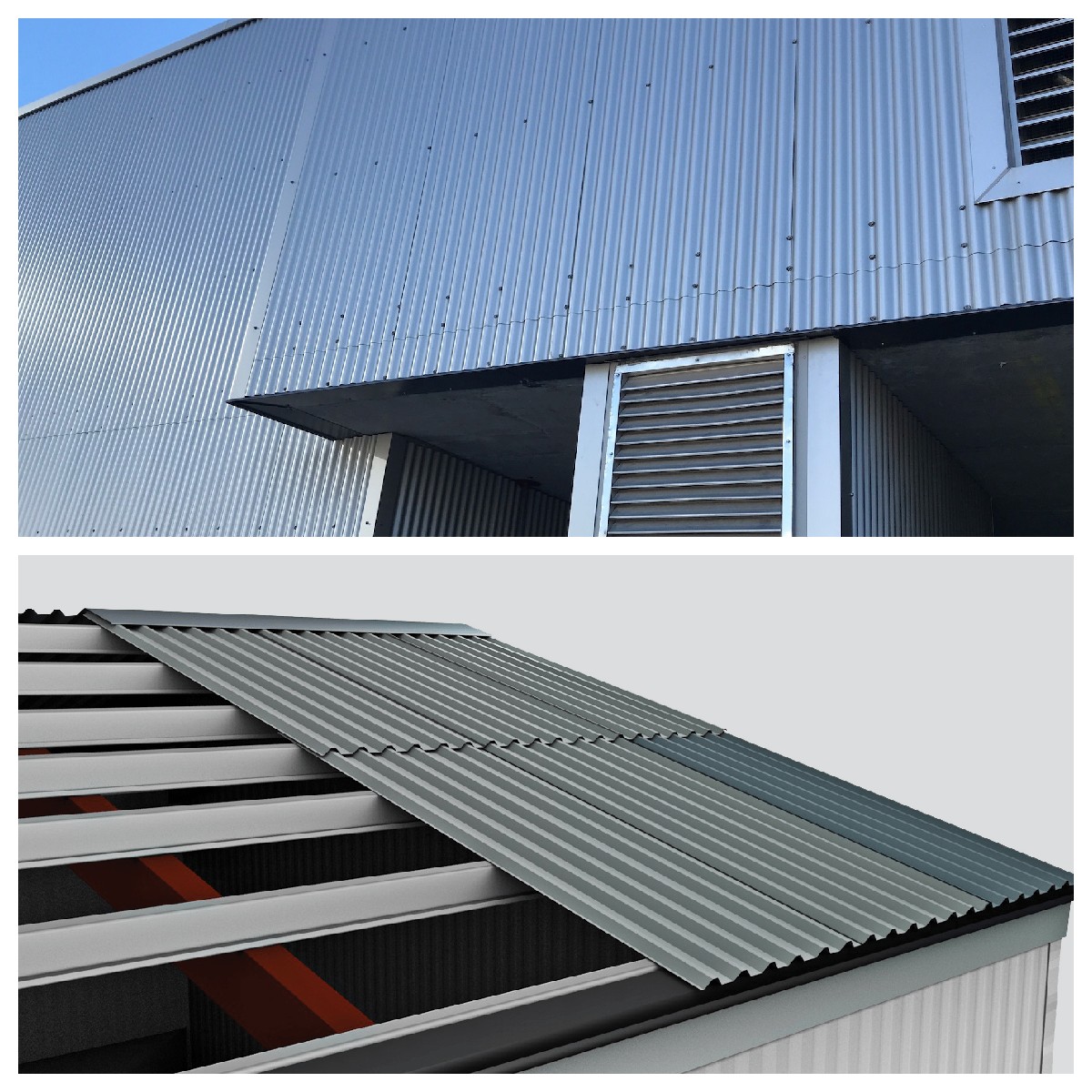

Corrugated roofing panel

Dingang

7610900000

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Aluminium Roofing Sheet |

| Size | Thickness: 0.2-1.5MM Width: 650-1050 MM Length: 1000-12000 MM |

| Tolerance | Thickness: +/-0.02mm, Width:+/-2mm |

| Typical Grade | 1050,1060,1100,2024,2240,3003,5052,5754... |

| Standard | ASTM,DIN,JIS,BS,GB/T |

| Certificate | ISO, SGS, BV.... |

| Packing | standard export package (waterproof kraft paper) |

| Application | - Chemical industry equipment,Industrial Tanks -Medical equioment,Food industry,Construction,Kitchen utensils - Electricequipment,Building Material - Reflector,Mirror,Interior-Exterior decoration for building |

HOW TO INSTALL RED CORRUGATED ALUMINUM ROOFING PANELS

Materials and Tools You'll Need:

1.Painted aluminum roofing sheets

2.Roofing underlayment (such as felt or synthetic underlayment)

3.Roofing nails or screws

4.Roofing adhesive/sealant

5.Roofing nails or screws

6.Metal cutting tools (tin snips, circular saw with a metal-cutting blade)

7.Measuring tape

8.Chalk line

9.Roofing safety equipment (harness, hard hat, non-slip shoes, etc.)

10.Ladder or scaffolding

11.Screw gun or hammer

Installation Steps:

1.Prepare the Roof: Ensure that the roof deck is clean, dry, and free from debris. Repair any damaged areas and make sure the roof's structure is sound.

2.Install Underlayment: Apply roofing underlayment to the entire roof surface according to the manufacturer's instructions. This helps to provide an additional layer of protection against water infiltration.

3.Measure and Plan: Measure the dimensions of the roof and calculate the number of roofing sheets you'll need. Plan the layout to minimize the number of cuts required. Use a chalk line to mark reference lines for the first row of roofing sheets.

4.Cutting: Use metal cutting tools to cut the aluminum roofing sheets to the required lengths and shapes. Make sure to wear appropriate safety gear when cutting metal.

5.Start Installation: Begin at the lower edge of the roof and work your way up. Align the first sheet with the chalk line and the roof's edge. Leave a slight overhang at the eaves, which can be trimmed later.

6.Fasten Sheets: Attach the roofing sheets using roofing nails or screws. Use fasteners with neoprene washers or gaskets to prevent water penetration. Fasten the sheets according to the manufacturer's recommendations, usually along the raised ridges of the sheets.

7.Overlap: When installing subsequent sheets, overlap each sheet by the recommended amount to ensure proper water shedding. The exact overlap may vary depending on the profile of the roofing sheets.

8.Sealing: Apply roofing adhesive or sealant along the overlapping edges and under the screw heads to create a watertight seal.

9.Ridge and Flashing: Install ridge caps at the peak of the roof and any necessary flashing to seal around roof penetrations such as vents, chimneys, and skylights.

10.Trimming: Once all the sheets are in place, trim any excess overhang at the eaves using metal cutting tools.

11.Finishing Touches: Inspect the entire installation for any loose fasteners, gaps, or imperfections. Make sure that all seams are properly sealed and that the roof is secure.

COMPARSION OF PAINTED STEEL PANELS AND PAINTED ALUMINUM ROOFING PANELS

Painted steel panels and painted aluminum roofing panels are commonly used materials for roofing and wall cladding in construction. The choice between these materials depends on factors such as budget, aesthetics, and environmental considerations. Here is a comparison of the two:

Material Composition:

Painted Steel Panels: These panels are typically made from galvanized steel or galvalume (steel coated with aluminum-zinc alloy) and then coated with paint. Steel panels are known for their strength and durability.

Painted Aluminum Roofing Panels: These panels are made entirely from aluminum, making them lightweight, corrosion-resistant, and long-lasting.

Durability:

Painted Steel Panels: Steel panels are strong and durable, suitable for areas with high wind loads and heavy snow. However, they are prone to corrosion over time, which can affect their lifespan.

Painted Aluminum Roofing Panels: Aluminum panels are corrosion-resistant, making them ideal for coastal areas or high-humidity environments. While lightweight, they are not as strong as steel, so they may not be the best choice for extreme weather conditions.

Weight:

Painted Steel Panels: Steel panels are heavier than aluminum panels, which can make installation more challenging and may require additional structural support.

Painted Aluminum Roofing Panels: Aluminum panels are lightweight, making them easier to handle during installation and exerting less stress on the underlying structure.

Cost:

Painted Steel Panels: Steel panels are generally less expensive than aluminum panels upfront. However, long-term maintenance costs may be higher due to the potential for corrosion.

Painted Aluminum Roofing Panels: Aluminum panels are initially more expensive but tend to have lower maintenance costs over their lifespan due to their corrosion resistance.

Aesthetics:

Painted Steel Panels: Steel panels come in various profiles and colors, providing design flexibility and a classic, industrial look.

Painted Aluminum Roofing Panels: Aluminum panels are available in different colors and profiles, offering a sleek, modern appearance.

Environmental Impact:

Painted Steel Panels: Steel is a recyclable material, but its production process can be energy-intensive. The potential for corrosion may also lead to earlier replacements, impacting long-term sustainability.

Painted Aluminum Roofing Panels: Aluminum is highly recyclable and retains its properties when recycled, making it an environmentally friendly choice. Its corrosion resistance can also result in a longer lifespan, reducing the need for replacements.

HOW TO PACKING CORRUGATED ALUMINUM ROOFING PANELS WHEN EXPORT

Inspect the Painted Aluminum Sheets: Before packing, inspect the painted aluminum sheets for any damage, scratches, or imperfections. Only pack sheets that meet quality standards.

Clean the Sheets: Ensure that the painted surface is clean and free from dust, dirt, and debris. Use a soft cloth or a gentle cleaning solution if necessary.

Protective Coating: If the painted surface is sensitive, consider applying a protective coating or film to prevent scratches during handling and shipping.

Materials Needed: Gather the necessary packing materials, including:

Cardboard or Wooden Crates: These provide sturdy protection for the sheets.

Bubble Wrap: Use bubble wrap to wrap individual sheets and provide cushioning.

Corner Protectors: These protect the edges of the sheets from impact.

Foam or Styrofoam Sheets: Place foam sheets between layers of painted aluminum sheets to prevent direct contact.

Plastic Sheeting: Use plastic sheeting to shield the sheets from moisture.

Strapping or Packing Tape: Secure the packaging materials in place.

Wrapping Individual Sheets: Place a sheet of bubble wrap on a flat surface.

Gently place the painted aluminum sheet on the bubble wrap.

Wrap the sheet tightly in the bubble wrap, ensuring all edges are covered.

Secure the bubble wrap in place with packing tape.

Creating Layers:

Place foam or Styrofoam sheets on the bottom of the crate.

Carefully stack the wrapped aluminum sheets in a single layer on top of the foam sheets.

Place corner protectors on the top of the first layer.

Adding Additional Layers:

Add another layer of foam or Styrofoam sheets on top of the first layer of aluminum sheets.

Place the next layer of wrapped aluminum sheets on top of the foam, alternating the placement to avoid direct alignment of corners.

Continue this process until all sheets are packed, placing foam between each layer.

Securing and Sealing:

Once all layers are stacked, place foam on top.

Seal the crate with packing tape.

Use strapping to reinforce the crate's structure.

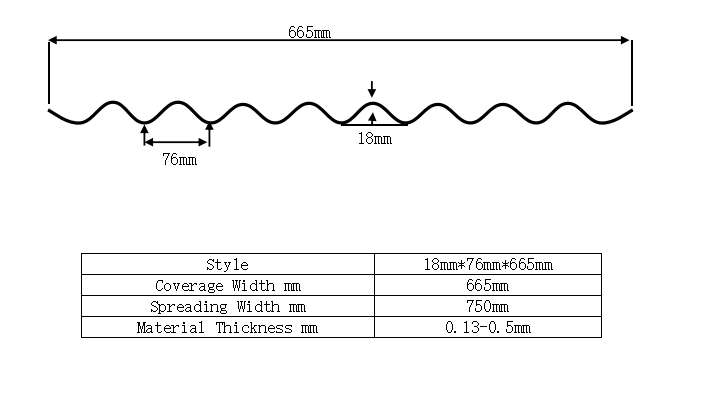

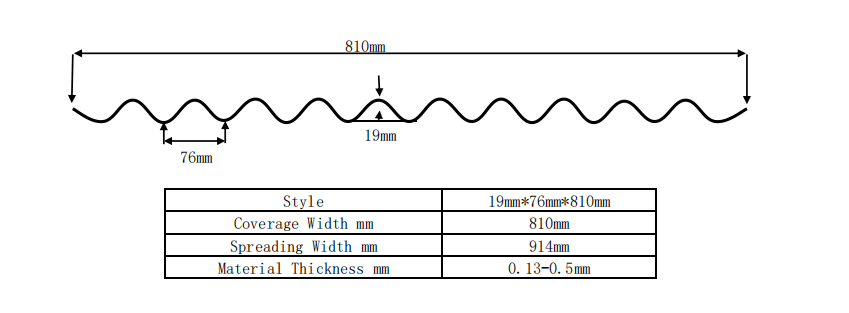

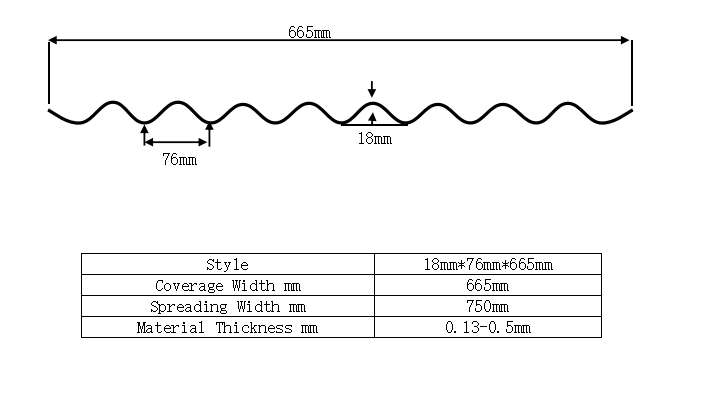

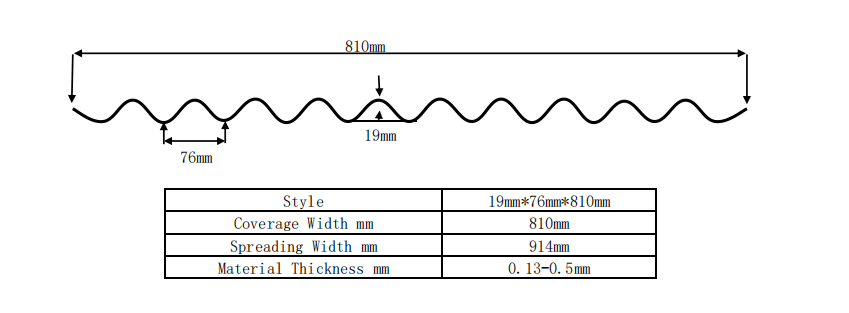

SIZE OF CORRUGATED ALUMIUM ROOFING PANEL

Welcome to contact us for more product details.

| Product Name | Aluminium Roofing Sheet |

| Size | Thickness: 0.2-1.5MM Width: 650-1050 MM Length: 1000-12000 MM |

| Tolerance | Thickness: +/-0.02mm, Width:+/-2mm |

| Typical Grade | 1050,1060,1100,2024,2240,3003,5052,5754... |

| Standard | ASTM,DIN,JIS,BS,GB/T |

| Certificate | ISO, SGS, BV.... |

| Packing | standard export package (waterproof kraft paper) |

| Application | - Chemical industry equipment,Industrial Tanks -Medical equioment,Food industry,Construction,Kitchen utensils - Electricequipment,Building Material - Reflector,Mirror,Interior-Exterior decoration for building |

HOW TO INSTALL RED CORRUGATED ALUMINUM ROOFING PANELS

Materials and Tools You'll Need:

1.Painted aluminum roofing sheets

2.Roofing underlayment (such as felt or synthetic underlayment)

3.Roofing nails or screws

4.Roofing adhesive/sealant

5.Roofing nails or screws

6.Metal cutting tools (tin snips, circular saw with a metal-cutting blade)

7.Measuring tape

8.Chalk line

9.Roofing safety equipment (harness, hard hat, non-slip shoes, etc.)

10.Ladder or scaffolding

11.Screw gun or hammer

Installation Steps:

1.Prepare the Roof: Ensure that the roof deck is clean, dry, and free from debris. Repair any damaged areas and make sure the roof's structure is sound.

2.Install Underlayment: Apply roofing underlayment to the entire roof surface according to the manufacturer's instructions. This helps to provide an additional layer of protection against water infiltration.

3.Measure and Plan: Measure the dimensions of the roof and calculate the number of roofing sheets you'll need. Plan the layout to minimize the number of cuts required. Use a chalk line to mark reference lines for the first row of roofing sheets.

4.Cutting: Use metal cutting tools to cut the aluminum roofing sheets to the required lengths and shapes. Make sure to wear appropriate safety gear when cutting metal.

5.Start Installation: Begin at the lower edge of the roof and work your way up. Align the first sheet with the chalk line and the roof's edge. Leave a slight overhang at the eaves, which can be trimmed later.

6.Fasten Sheets: Attach the roofing sheets using roofing nails or screws. Use fasteners with neoprene washers or gaskets to prevent water penetration. Fasten the sheets according to the manufacturer's recommendations, usually along the raised ridges of the sheets.

7.Overlap: When installing subsequent sheets, overlap each sheet by the recommended amount to ensure proper water shedding. The exact overlap may vary depending on the profile of the roofing sheets.

8.Sealing: Apply roofing adhesive or sealant along the overlapping edges and under the screw heads to create a watertight seal.

9.Ridge and Flashing: Install ridge caps at the peak of the roof and any necessary flashing to seal around roof penetrations such as vents, chimneys, and skylights.

10.Trimming: Once all the sheets are in place, trim any excess overhang at the eaves using metal cutting tools.

11.Finishing Touches: Inspect the entire installation for any loose fasteners, gaps, or imperfections. Make sure that all seams are properly sealed and that the roof is secure.

COMPARSION OF PAINTED STEEL PANELS AND PAINTED ALUMINUM ROOFING PANELS

Painted steel panels and painted aluminum roofing panels are commonly used materials for roofing and wall cladding in construction. The choice between these materials depends on factors such as budget, aesthetics, and environmental considerations. Here is a comparison of the two:

Material Composition:

Painted Steel Panels: These panels are typically made from galvanized steel or galvalume (steel coated with aluminum-zinc alloy) and then coated with paint. Steel panels are known for their strength and durability.

Painted Aluminum Roofing Panels: These panels are made entirely from aluminum, making them lightweight, corrosion-resistant, and long-lasting.

Durability:

Painted Steel Panels: Steel panels are strong and durable, suitable for areas with high wind loads and heavy snow. However, they are prone to corrosion over time, which can affect their lifespan.

Painted Aluminum Roofing Panels: Aluminum panels are corrosion-resistant, making them ideal for coastal areas or high-humidity environments. While lightweight, they are not as strong as steel, so they may not be the best choice for extreme weather conditions.

Weight:

Painted Steel Panels: Steel panels are heavier than aluminum panels, which can make installation more challenging and may require additional structural support.

Painted Aluminum Roofing Panels: Aluminum panels are lightweight, making them easier to handle during installation and exerting less stress on the underlying structure.

Cost:

Painted Steel Panels: Steel panels are generally less expensive than aluminum panels upfront. However, long-term maintenance costs may be higher due to the potential for corrosion.

Painted Aluminum Roofing Panels: Aluminum panels are initially more expensive but tend to have lower maintenance costs over their lifespan due to their corrosion resistance.

Aesthetics:

Painted Steel Panels: Steel panels come in various profiles and colors, providing design flexibility and a classic, industrial look.

Painted Aluminum Roofing Panels: Aluminum panels are available in different colors and profiles, offering a sleek, modern appearance.

Environmental Impact:

Painted Steel Panels: Steel is a recyclable material, but its production process can be energy-intensive. The potential for corrosion may also lead to earlier replacements, impacting long-term sustainability.

Painted Aluminum Roofing Panels: Aluminum is highly recyclable and retains its properties when recycled, making it an environmentally friendly choice. Its corrosion resistance can also result in a longer lifespan, reducing the need for replacements.

HOW TO PACKING CORRUGATED ALUMINUM ROOFING PANELS WHEN EXPORT

Inspect the Painted Aluminum Sheets: Before packing, inspect the painted aluminum sheets for any damage, scratches, or imperfections. Only pack sheets that meet quality standards.

Clean the Sheets: Ensure that the painted surface is clean and free from dust, dirt, and debris. Use a soft cloth or a gentle cleaning solution if necessary.

Protective Coating: If the painted surface is sensitive, consider applying a protective coating or film to prevent scratches during handling and shipping.

Materials Needed: Gather the necessary packing materials, including:

Cardboard or Wooden Crates: These provide sturdy protection for the sheets.

Bubble Wrap: Use bubble wrap to wrap individual sheets and provide cushioning.

Corner Protectors: These protect the edges of the sheets from impact.

Foam or Styrofoam Sheets: Place foam sheets between layers of painted aluminum sheets to prevent direct contact.

Plastic Sheeting: Use plastic sheeting to shield the sheets from moisture.

Strapping or Packing Tape: Secure the packaging materials in place.

Wrapping Individual Sheets: Place a sheet of bubble wrap on a flat surface.

Gently place the painted aluminum sheet on the bubble wrap.

Wrap the sheet tightly in the bubble wrap, ensuring all edges are covered.

Secure the bubble wrap in place with packing tape.

Creating Layers:

Place foam or Styrofoam sheets on the bottom of the crate.

Carefully stack the wrapped aluminum sheets in a single layer on top of the foam sheets.

Place corner protectors on the top of the first layer.

Adding Additional Layers:

Add another layer of foam or Styrofoam sheets on top of the first layer of aluminum sheets.

Place the next layer of wrapped aluminum sheets on top of the foam, alternating the placement to avoid direct alignment of corners.

Continue this process until all sheets are packed, placing foam between each layer.

Securing and Sealing:

Once all layers are stacked, place foam on top.

Seal the crate with packing tape.

Use strapping to reinforce the crate's structure.

SIZE OF CORRUGATED ALUMIUM ROOFING PANEL

Welcome to contact us for more product details.

Products

Quick Links

Contact Us