What Gauge Aluminum Is the Strongest?

Introduction

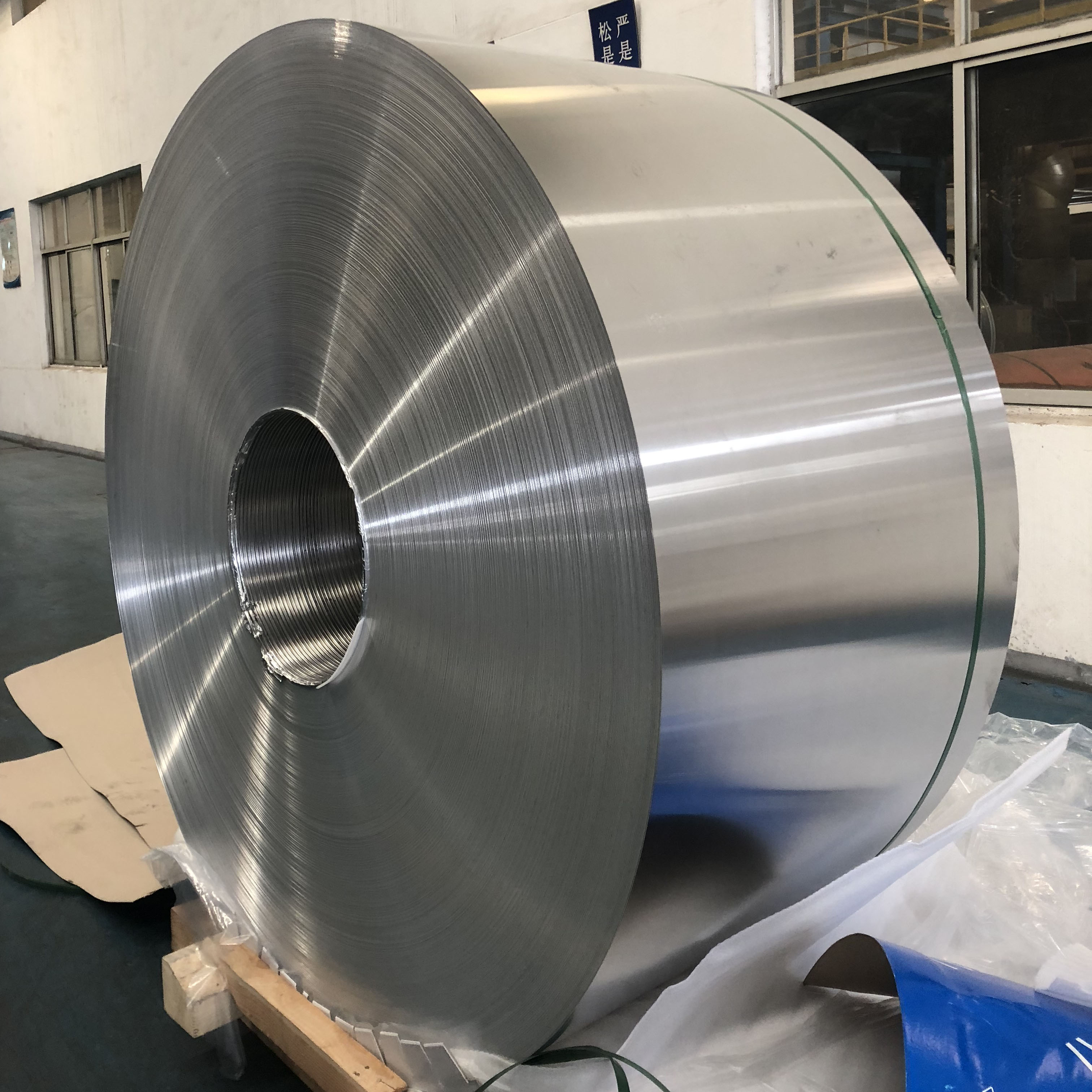

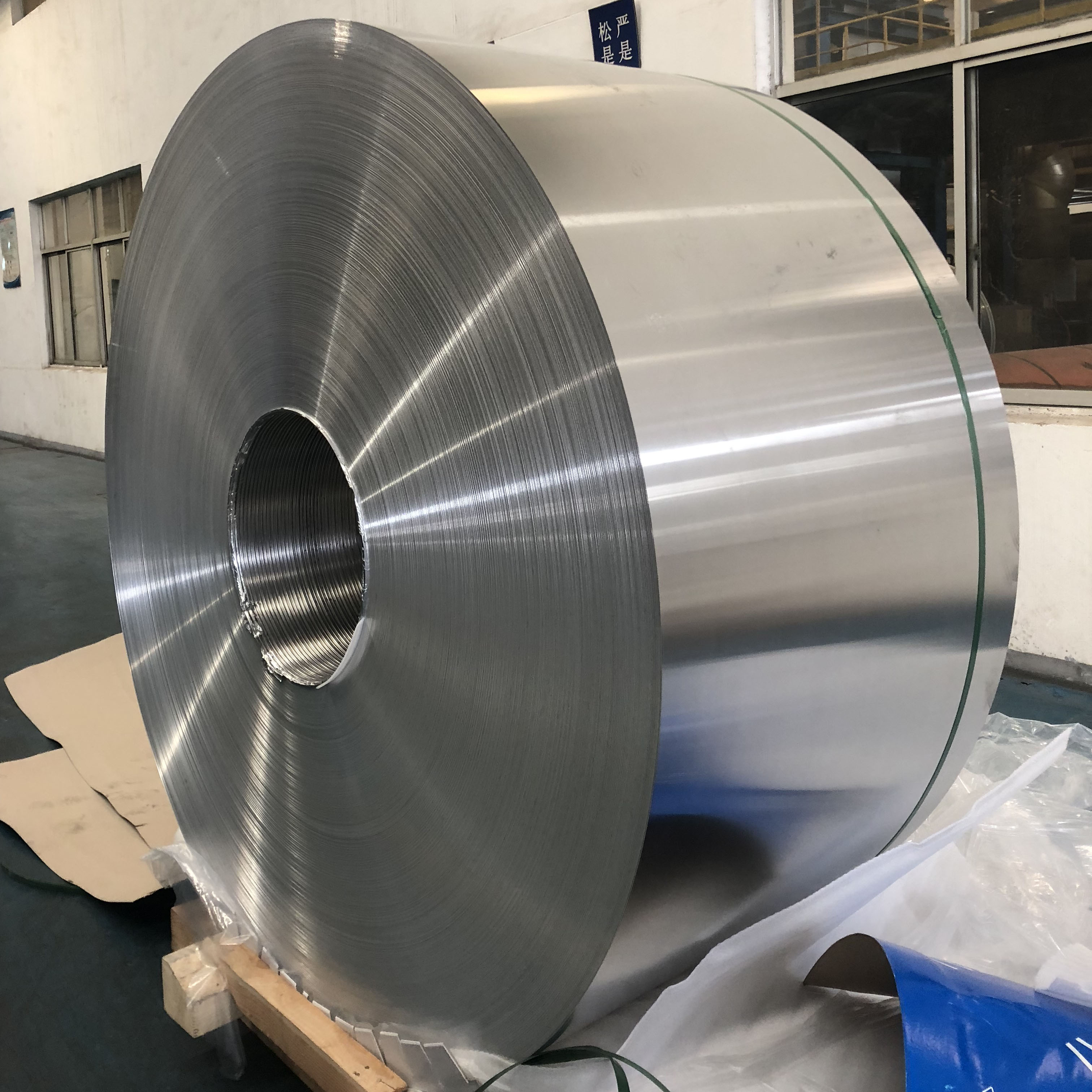

Aluminum, a versatile and widely used material, comes in various thicknesses or gauges. But what gauge aluminum is the strongest? This question is of paramount importance in industries ranging from aerospace to construction. In this comprehensive guide, we will delve into the world of aluminum gauges and explore the factors that determine their strength. By the end, you'll have a clear understanding of which aluminum gauge suits your specific needs.

Understanding Gauge in Aluminum

Gauge is a measurement that indicates the thickness of aluminum sheets or foils. The lower the gauge number, the thicker the material. For example, a 6 - gauge aluminum is thicker than a 10 - gauge aluminum.

Strength and Thickness Relationship

In general, thicker aluminum (lower gauge number) is stronger. For structural applications, such as in the construction of buildings, bridges, or heavy - duty machinery frames, thicker gauges like 1/4 - inch (6.35 mm) or 3/16 - inch (4.76 mm) aluminum (which would be a very low gauge number, around 4 - 6 gauge) are often used. These thicker gauges can better withstand heavy loads, high winds, and other external forces.

Alloy Composition Also Matters

The strength of aluminum is not only determined by its thickness. The alloy composition plays a significant role too. For example, alloys like 6061 and 7075 are known for their high strength. A 6061 - T6 aluminum alloy, even at a relatively thinner gauge, can have excellent strength - to - weight ratio. The T6 temper indicates that the alloy has been heat - treated and artificially aged to achieve a good combination of strength and ductility.

7075 aluminum alloy is even stronger, especially in applications where high - strength and lightweight materials are required, such as in the aerospace industry. It contains zinc as a major alloying element, which significantly enhances its strength.

Application - Dependent Strength

In applications where strength against puncture or impact is crucial, such as in the manufacturing of armor plates or some industrial equipment, the combination of a suitable alloy and an appropriate thickness (lower gauge) is considered. For example, for a bullet - resistant application, a thick (low - gauge) plate of a high - strength aluminum alloy like 5083 might be used. The 5083 alloy has good resistance to corrosion and high - strength properties, making it suitable for such demanding applications.

Comparison of aluminium alloys of different strengths

| Series | Typical Tensile Strength Range (MPa) | General Characteristics |

| 1xxx | 70 - 180 | High purity, excellent corrosion resistance, good conductivity, used for electrical conductors, decorative applications. |

| 3xxx | 140 - 280 | Moderate strength, good formability, used for cooking utensils, chemical equipment, building panels. |

| 5xxx | 180 - 350 | Good corrosion resistance, especially in marine environments, medium to high strength, used for marine vessels, automotive body panels. |

| 6xxx | 200 - 350 | Good combination of strength and formability, used for structural frames, architectural extrusions. |

| 7xxx | 480 - 650 | Very high strength, used in aerospace, high - stress mechanical parts. |

| 8xxx | Varies widely depending on specific alloy | Specialized alloys with various properties for niche applications. |

Conclusion

In conclusion, the strength of aluminum varies depending on several factors, including alloy composition, heat treatment, thickness, and manufacturing process. Understanding these factors is crucial when selecting the right aluminum gauge for your project. Whether you're in the aerospace, automotive, or construction industry, aluminum's strength is a key attribute that shouldn't be overlooked.

FAQs on Aluminum Strength

1. How Does Aluminum Compare to Steel in Terms of Strength?

Aluminum is less dense than steel, which means it is lighter. However, steel generally has higher tensile and yield strengths compared to aluminum. The choice between the two depends on specific application requirements.

2. Can Aluminum be Strengthened?

Yes, aluminum can be strengthened through various methods, including alloying, heat treatment, and cold working. These processes can enhance its mechanical properties for specific purposes.

3. What Are the Different Types of Aluminum Alloys and Their Strengths?

Aluminum alloys come in various grades, each with its unique set of mechanical properties. Some common aluminum alloys and their strengths include 6061-T6 (high strength and excellent corrosion resistance) and 7075-T6 (very high strength).

4. What Factors Affect the Strength of Aluminum Alloys?

The strength of aluminum alloys can be influenced by factors such as alloy composition, heat treatment, and the presence of impurities. Proper alloy selection and processing are crucial for achieving desired strength levels.

5. Is Aluminum Prone to Corrosion, and How Does it Affect Strength?

Aluminum is susceptible to corrosion, especially in certain environments. Corrosion can weaken aluminum over time, compromising its strength. Protective coatings and alloys with corrosion resistance can mitigate this effect.

6. Can Aluminum be Used for Structural Applications?

Yes, aluminum is commonly used in structural applications, especially in industries like aerospace and construction. Its strength, combined with its lightweight nature, makes it an attractive choice for various structural components.

7. What Safety Precautions Should be Taken When Working with High-Strength Aluminum?

Working with high-strength aluminum requires proper safety precautions, including wearing appropriate protective gear and using specialized equipment. Ensuring proper training and following industry guidelines is essential.

8. Are There Any Limitations to Aluminum's Strength?

While aluminum offers many advantages, it does have limitations. At very high loads, aluminum can deform or fail, making it unsuitable for some heavy-duty applications that require the ultimate strength of materials like steel.

9. How Can I Determine the Strength of Aluminum for My Specific Project?

The strength of aluminum for your project depends on various factors, including alloy selection, manufacturing processes, and the load-bearing requirements. Consult with materials engineers or use specialized software to calculate the strength based on your project's specifications.

When selecting an aluminum alloy, it is crucial to consider your specific application. For applications requiring good formability and moderate strength like household utensils, 3xxx series might be suitable. If high strength for aerospace or heavy machinery is needed, 7xxx series is a better choice. 6xxx series offers a balance for structural frames. Matching the alloy's strength to the application ensures optimal performance and durability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg