Embossed aluminum sheet

Dingang

7610900000

| Availability: | |

|---|---|

DESCRIPTION

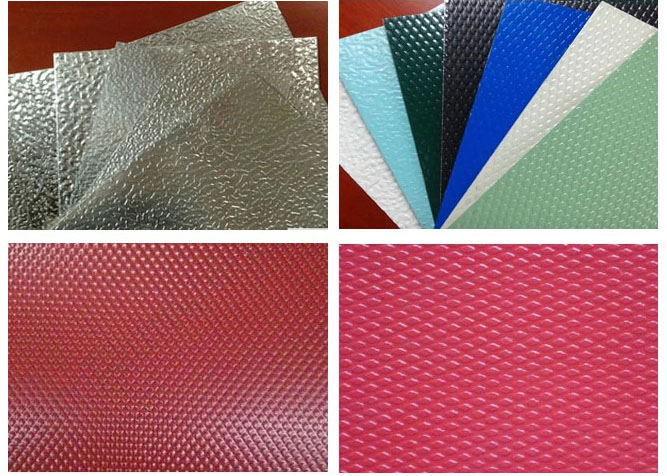

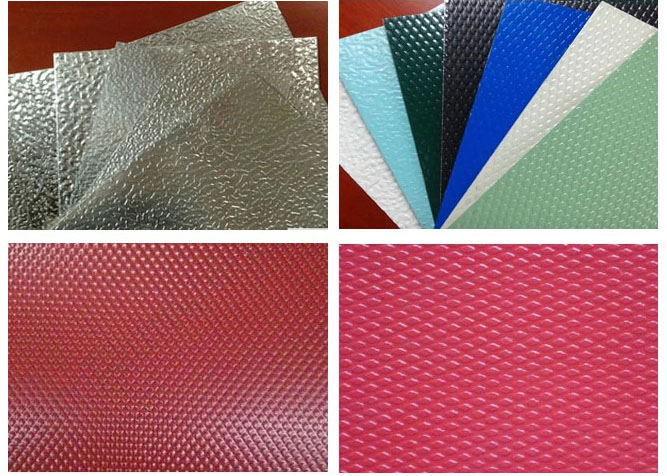

The Orange Peel Aluminum Sheet is a versatile and visually appealing aluminum product designed to meet a wide range of industrial and decorative needs. It derives its name from the distinctive textured surface, which closely resembles the dimpled pattern of an orange peel. This unique texture not only enhances the sheet's aesthetic appeal but also offers practical advantages in terms of grip, durability, and resistance to wear and tear.

Orange peel aluminum sheet is a type of aluminum sheet that has a textured surface resembling the skin or texture of an orange peel. This texture is not a naturally occurring feature of aluminum but is intentionally created through a manufacturing process known as "embossing" or "orange peel embossing."

ORANGE PEEL ALUMINUM SHEET KEY FEATURES

Textured Surface: The orange peel pattern provides a non-slip surface, making it ideal for applications where grip and safety are paramount.

Aesthetic Appeal: The distinctive texture adds an attractive and visually interesting element to any project, making it suitable for architectural and interior design purposes.

Durable and Resilient: Constructed from high-quality aluminum alloy, this sheet is corrosion-resistant, weather-resistant, and capable of withstanding harsh environments.

Easy to Work With: The sheet can be easily cut, bent, or shaped to suit specific requirements, making it a versatile material for various applications.

ALUMINUM ALLOY SHEET DETAILS

1060 3003 5052 6061 Aluminum Plate Embossed | |

Commodity | Aluminum Sheet, Aluminum Plate, AL5052 Aluminum, Aluminum Coil Sheet |

Material & Grade | 1050, 1060, 1100, 2A12, 2A14, 3003, 3004, 3005, 3014, 3015, 5052, 5083, 5086, 5251, 5005, 5154, 5754, 6061, 6063... |

Size | Thickness: 0.3mm - 200mm |

Temper | O-H114, T3-T8 |

Standard | ASTM B209 GB/T3880 |

Pattern | Diamond, Five Bar, 3 Bar, Tear, Orange Peel Pattern, Stucco Embossed Pattern |

Surface | Mill, Brush, Blast, Mirror, Embossed, Checkered, etc. |

MOQ | 2 Ton / Size |

ORANGE PEEL ALUMINUM SHEET APPLICATION

Decorative Finishes: These are used in interior and exterior design projects to create unique and eye-catching surfaces, such as wall panels, ceilings, and decorative trim.

Non-Slip Surfaces: They are applied in places where slip resistance is crucial, like staircases, ramps, and flooring in industrial settings.

Transportation: This material is utilized in the automotive and aerospace industries for applications such as flooring, interior trim, and decorative panels.

Household Appliances: It is used for the production of textured appliance surfaces, enhancing both functionality and aesthetics.

Construction: It is ideal for construction applications, including roofing, siding, and architectural elements.

Aluminum Sheet properties:

•Strong yet lightweight

•Resistant to corrosion, especially in outdoor and extreme environments

•Easily formable due to its relatively low melting point

•Fireproof, unless extremely thin

•Good heat and electrical conductivity, making it suitable for electronic components

•Highly recyclable

•Durable and low maintenance

•Reflective, making it ideal for energy-efficient buildings and lighting

•Available in various thicknesses and custom sizes (at Click Metal)

•Food-grade, commonly used for food containers

ORANGE PEEL ALUMINUM SHEET SPECIFICATION

• Material: High-quality aluminum alloy

• Texture: Orange peel pattern

• Thickness: Customizable to meet specific project requirements

• Width and Length: Available in various dimensions

• Finish: Mill finish or custom coatings (such as anodized or painted)

WHY CHOOSE US?

1. More than 15 years of experience in aluminum business.

2. Competitive price and high quality materials.

3. Worry-free quality and quantity.

4. Attitude and sense of responsibility to serve customers wholeheartedly.

5. Quick response to emails.

6.24 hours online service.

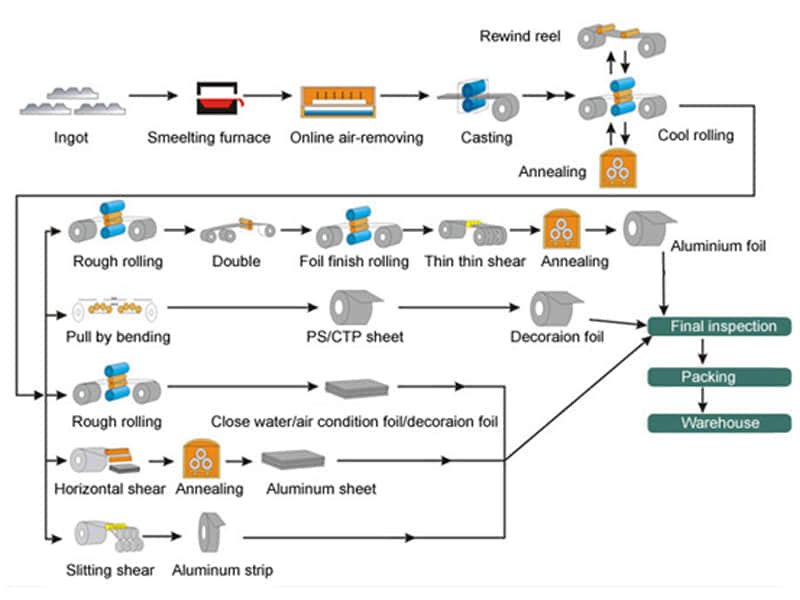

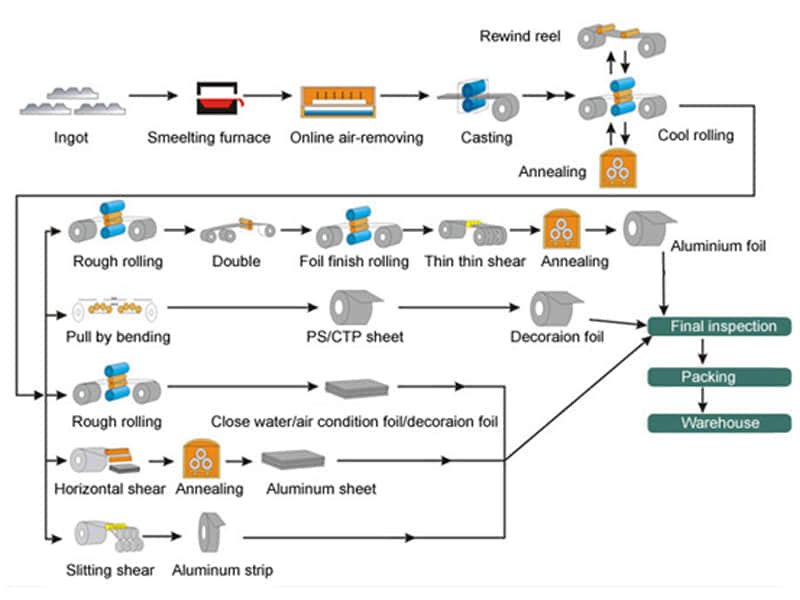

ALUMINUM PRODUCTION PROCESSING

If you're looking to purchase aluminum sheets, follow these tips to ensure a straightforward process and meet your specific needs:

1. Determine Your Requirements:

Identify the size, thickness, and grade of aluminum sheet needed for your project.

Consider the alloy type: Common options are 3003, 5052, and 6061, each with different properties.

2. Understand Aluminum Alloys:

Different aluminum alloys offer varying properties like strength, corrosion resistance, and weldability.

Research which alloy is best suited for your application.

3.Sheet Thickness:

Accurately measure or calculate the required thickness for your project.

Keep in mind that thinner sheets are more flexible, while thicker sheets are sturdier.

4.Sheet Size:

Determine the dimensions required for your aluminum sheet.

Check if the supplier offers custom cutting services if needed.

5.Surface Finish:

Aluminum sheets come in various finishes: mill finish (raw), brushed, anodized, or painted.

Choose the finish that best suits your project's aesthetics and performance requirements.

6.Quality Standards:

Ensure the aluminum sheet meets relevant quality standards such as ASTM or ISO.

7.Supplier Selection:

Research and select a reputable aluminum sheet supplier or distributor.

Read customer reviews, seek recommendations, and verify certifications and quality control processes.

8.Price Comparison:

Compare prices from multiple suppliers to get the best deal.

Be cautious of unusually low prices, as they may indicate lower-quality material.

9.Shipping and Handling:

Consider shipping costs and lead times, particularly when purchasing online or from distant suppliers.

Factor in handling and storage requirements, especially for long-distance transportation.

10.Inspection Upon Delivery:

Thoroughly inspect the aluminum sheets upon delivery for any damage, defects, or discrepancies.

Immediately notify the supplier if any issues are discovered.

11.Storage and Handling:

Store aluminum sheets in a clean, dry, and well-ventilated area to prevent corrosion.

Use proper handling equipment and techniques to avoid damage.

12.Safety Precautions:

When working with aluminum sheets, wear appropriate safety gear such as gloves and eye protection.

Follow safe cutting and handling practices to prevent injuries.

Recycling Consideration:

Aluminum is highly recyclable, so consider recycling any scraps or waste material from your project.

WAREHOUSE & DELIVERY

Sheet:

Coil:

Container Loading:

GET A QUOTE or REQUEST A FREE COLOR SAMPLE

DESCRIPTION

The Orange Peel Aluminum Sheet is a versatile and visually appealing aluminum product designed to meet a wide range of industrial and decorative needs. It derives its name from the distinctive textured surface, which closely resembles the dimpled pattern of an orange peel. This unique texture not only enhances the sheet's aesthetic appeal but also offers practical advantages in terms of grip, durability, and resistance to wear and tear.

Orange peel aluminum sheet is a type of aluminum sheet that has a textured surface resembling the skin or texture of an orange peel. This texture is not a naturally occurring feature of aluminum but is intentionally created through a manufacturing process known as "embossing" or "orange peel embossing."

ORANGE PEEL ALUMINUM SHEET KEY FEATURES

Textured Surface: The orange peel pattern provides a non-slip surface, making it ideal for applications where grip and safety are paramount.

Aesthetic Appeal: The distinctive texture adds an attractive and visually interesting element to any project, making it suitable for architectural and interior design purposes.

Durable and Resilient: Constructed from high-quality aluminum alloy, this sheet is corrosion-resistant, weather-resistant, and capable of withstanding harsh environments.

Easy to Work With: The sheet can be easily cut, bent, or shaped to suit specific requirements, making it a versatile material for various applications.

ALUMINUM ALLOY SHEET DETAILS

1060 3003 5052 6061 Aluminum Plate Embossed | |

Commodity | Aluminum Sheet, Aluminum Plate, AL5052 Aluminum, Aluminum Coil Sheet |

Material & Grade | 1050, 1060, 1100, 2A12, 2A14, 3003, 3004, 3005, 3014, 3015, 5052, 5083, 5086, 5251, 5005, 5154, 5754, 6061, 6063... |

Size | Thickness: 0.3mm - 200mm |

Temper | O-H114, T3-T8 |

Standard | ASTM B209 GB/T3880 |

Pattern | Diamond, Five Bar, 3 Bar, Tear, Orange Peel Pattern, Stucco Embossed Pattern |

Surface | Mill, Brush, Blast, Mirror, Embossed, Checkered, etc. |

MOQ | 2 Ton / Size |

ORANGE PEEL ALUMINUM SHEET APPLICATION

Decorative Finishes: These are used in interior and exterior design projects to create unique and eye-catching surfaces, such as wall panels, ceilings, and decorative trim.

Non-Slip Surfaces: They are applied in places where slip resistance is crucial, like staircases, ramps, and flooring in industrial settings.

Transportation: This material is utilized in the automotive and aerospace industries for applications such as flooring, interior trim, and decorative panels.

Household Appliances: It is used for the production of textured appliance surfaces, enhancing both functionality and aesthetics.

Construction: It is ideal for construction applications, including roofing, siding, and architectural elements.

Aluminum Sheet properties:

•Strong yet lightweight

•Resistant to corrosion, especially in outdoor and extreme environments

•Easily formable due to its relatively low melting point

•Fireproof, unless extremely thin

•Good heat and electrical conductivity, making it suitable for electronic components

•Highly recyclable

•Durable and low maintenance

•Reflective, making it ideal for energy-efficient buildings and lighting

•Available in various thicknesses and custom sizes (at Click Metal)

•Food-grade, commonly used for food containers

ORANGE PEEL ALUMINUM SHEET SPECIFICATION

• Material: High-quality aluminum alloy

• Texture: Orange peel pattern

• Thickness: Customizable to meet specific project requirements

• Width and Length: Available in various dimensions

• Finish: Mill finish or custom coatings (such as anodized or painted)

WHY CHOOSE US?

1. More than 15 years of experience in aluminum business.

2. Competitive price and high quality materials.

3. Worry-free quality and quantity.

4. Attitude and sense of responsibility to serve customers wholeheartedly.

5. Quick response to emails.

6.24 hours online service.

ALUMINUM PRODUCTION PROCESSING

If you're looking to purchase aluminum sheets, follow these tips to ensure a straightforward process and meet your specific needs:

1. Determine Your Requirements:

Identify the size, thickness, and grade of aluminum sheet needed for your project.

Consider the alloy type: Common options are 3003, 5052, and 6061, each with different properties.

2. Understand Aluminum Alloys:

Different aluminum alloys offer varying properties like strength, corrosion resistance, and weldability.

Research which alloy is best suited for your application.

3.Sheet Thickness:

Accurately measure or calculate the required thickness for your project.

Keep in mind that thinner sheets are more flexible, while thicker sheets are sturdier.

4.Sheet Size:

Determine the dimensions required for your aluminum sheet.

Check if the supplier offers custom cutting services if needed.

5.Surface Finish:

Aluminum sheets come in various finishes: mill finish (raw), brushed, anodized, or painted.

Choose the finish that best suits your project's aesthetics and performance requirements.

6.Quality Standards:

Ensure the aluminum sheet meets relevant quality standards such as ASTM or ISO.

7.Supplier Selection:

Research and select a reputable aluminum sheet supplier or distributor.

Read customer reviews, seek recommendations, and verify certifications and quality control processes.

8.Price Comparison:

Compare prices from multiple suppliers to get the best deal.

Be cautious of unusually low prices, as they may indicate lower-quality material.

9.Shipping and Handling:

Consider shipping costs and lead times, particularly when purchasing online or from distant suppliers.

Factor in handling and storage requirements, especially for long-distance transportation.

10.Inspection Upon Delivery:

Thoroughly inspect the aluminum sheets upon delivery for any damage, defects, or discrepancies.

Immediately notify the supplier if any issues are discovered.

11.Storage and Handling:

Store aluminum sheets in a clean, dry, and well-ventilated area to prevent corrosion.

Use proper handling equipment and techniques to avoid damage.

12.Safety Precautions:

When working with aluminum sheets, wear appropriate safety gear such as gloves and eye protection.

Follow safe cutting and handling practices to prevent injuries.

Recycling Consideration:

Aluminum is highly recyclable, so consider recycling any scraps or waste material from your project.

WAREHOUSE & DELIVERY

Sheet:

Coil:

Container Loading:

GET A QUOTE or REQUEST A FREE COLOR SAMPLE

Products

Quick Links

Contact Us