-

A Because aluminum offers better long-term reliability, corrosion resistance, and lower structural impact, especially in demanding environments.

-

A Yes.

-

A Aluminum roofing requires minimal but proactive maintenance to preserve its durability and appearance, focusing on preventive care and early issue detection:Regular Cleaning,Coating Inspection,Drainage Maintenance,Physical Damage Check,Avoid Harsh Chemicals.

-

A Yes.

-

A Yes.

-

A Normally from 0.5-3.0mm thickness.

-

A High-quality coatings such as PVDF offer excellent color retention and UV resistance, minimizing fading over long-term exposure.

-

A Yes.

-

A Aluminum roofing profiles include:

1.Corrugated sheets,

2.Trapezoidal panels,

3.Standing seam panels,

4.Custom roll-formed profiles.

-

A When correctly installed such as prodcued by sandwich panel , together with underlay,cobined with proper insulation,Aluminum roofing noise level will much better than s are other metal roofing systems.

-

A Yes.

-

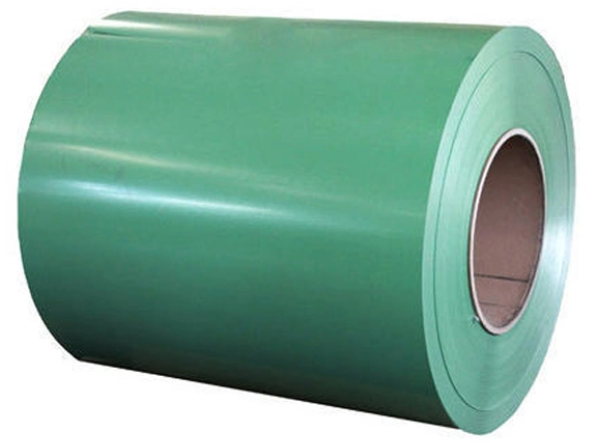

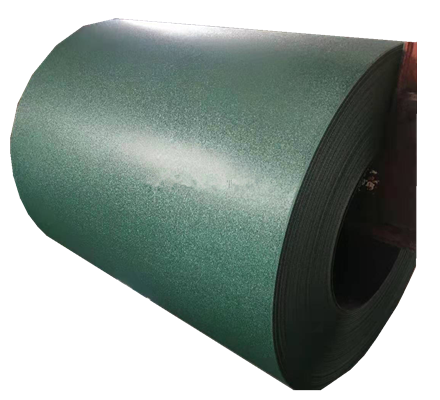

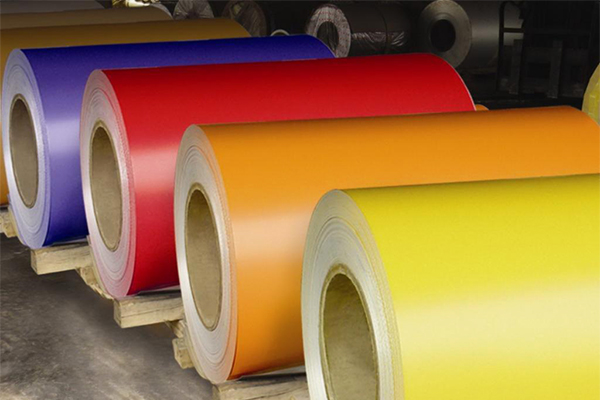

A PE Coating will be last 8-12 years,

HDP or SMP coating will be last round 15 years.

PVDF coating will be as long as 25 years or even more.

-

A HDP,SMP,PVDF,PE.

-

A Yes.

-

A In real projects, aluminum roofing outperforms steel roofing in key aspects like weight, corrosion resistance, and long-term maintenance, though steel may offer lower initial costs in some cases. Aluminum’s low density (2.7 g/cm³ vs. steel’s 7.85 g/cm³) makes it significantly lighter, reducing structural load and installation complexity—critical for large-span or retrofitted roofs. Its natural corrosion resistance (enhanced by alloys like 5052/5083 with Mg/Cr) eliminates rust risks in harsh environments (coastal, industrial), unlike steel which relies on coatings that degrade over time, requiring frequent repainting or galvanizing. Aluminum also boasts a superior strength-to-weight ratio, enabling thinner profiles for equivalent load-bearing capacity, while steel demands thicker gauges for similar strength. Maintenance-wise, aluminum’s durable pre-painted coatings (e.g., PVDF, 10–20-year lifespan) minimize upkeep, whereas steel roofs often need periodic rust prevention. Though steel may be cheaper upfront, aluminum’s longevity (30+ years vs. steel’s 15–25 with maintenance) and lower lifecycle costs make it preferable for projects prioritizing durability, aesthetics (custom colors/textures), and sustainability (100% recyclability). Steel, however, remains viable for budget-focused applications in mild climates where corrosion risks are low.

-

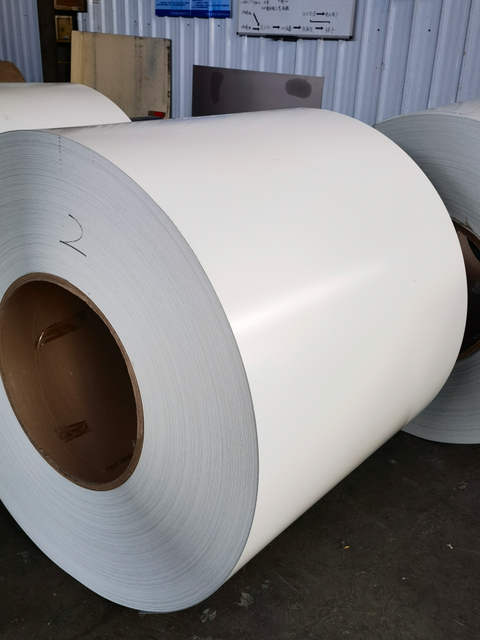

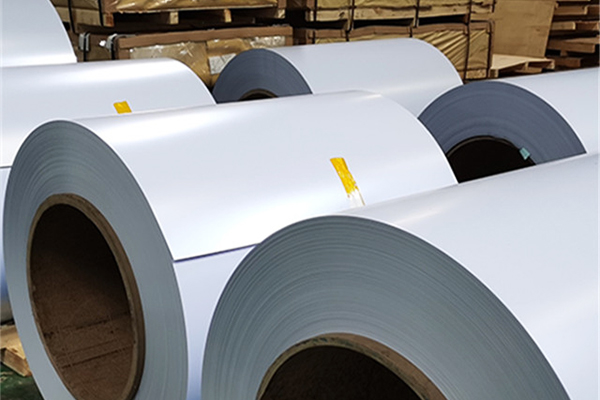

A Color coated aluminum is widely used in modern roofing systems because it uniquely combines aesthetic appeal with exceptional functional performance tailored to outdoor demands. Its pre-coated surface, featuring printed or digitally applied patterns (such as wood grain, stone, or solid colors), elevates architectural design while the aluminum substrate provides inherent advantages: lightweight construction reduces structural load, high strength resists deformation, and natural corrosion resistance ensures longevity. The protective coating further enhances durability by shielding against UV radiation, rain, and temperature fluctuations, preventing fading, chalking, or peeling—minimizing maintenance needs over decades. Additionally, its ease of fabrication into complex roof shapes, combined with optional thermal insulation or reflective properties (in some variants) that aid energy efficiency, aligns with modern priorities for sustainable, low-maintenance building solutions. This blend of visual flexibility, robust performance, and cost-effectiveness makes it an ideal choice for contemporary roofs seeking both style and reliability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg

GENERAL PARAMETERS

GENERAL PARAMETERS