What Is Aluminum Coil Coating?

Aluminum coil coating is a technology that applies a protective coating to the surface of aluminum coils, enhancing their corrosion resistance, weatherability, and decorative properties. Widely used in applications such as architectural curtain walls, appliance panels, roofing materials, and packaging, aluminum coil coatings not only improve the appearance of aluminum but also significantly extend its service life.

Main Functions and Applications of Aluminum Coil Coatings

The primary roles of aluminum coil coatings include:

1. Protection:

The coating prevents aluminum from corroding or aging due to environmental factors like moisture, acid rain, or UV rays.

2. Decoration:

Coatings offer a wide range of colors and gloss levels, catering to diverse aesthetic requirements.

3. Functional Enhancement:

Some coatings, such as fluorocarbon coatings, improve scratch resistance and self-cleaning properties.

Types and Characteristics of Coating Materials

Classification and Basic Principles of Coatings

Coatings can be categorized by:

· Composition:

Such as polyester coatings, fluorocarbon coatings, acrylic coatings, etc.

· Application:

Such as architectural, industrial, or specialized coatings.

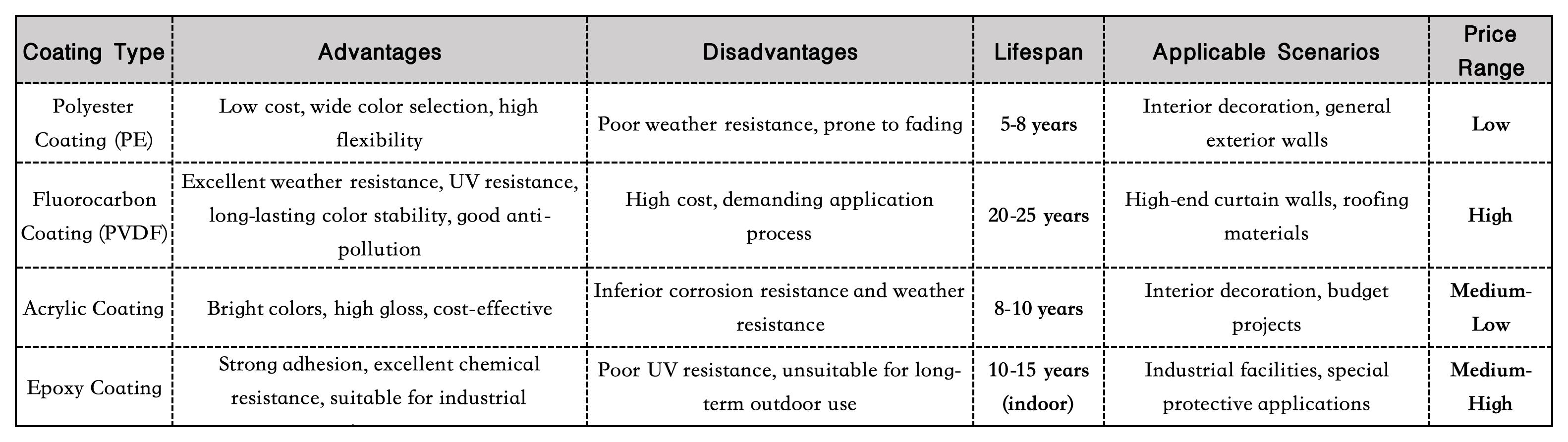

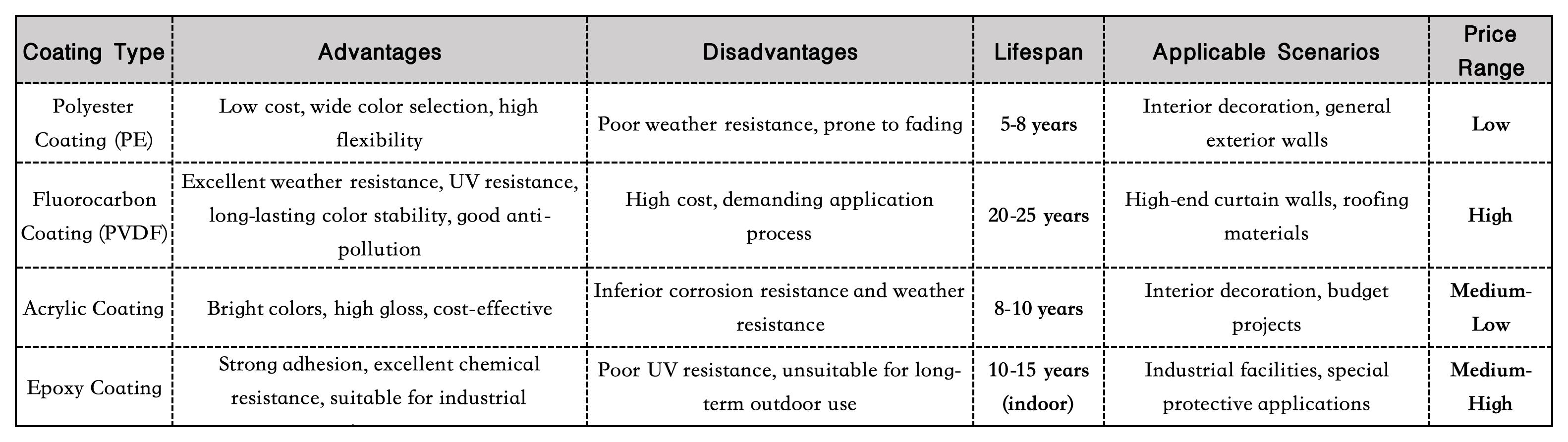

Detailed Overview of Common Coating Types

Polyester Coating (PE Coating)

Polyester coatings are cost-effective with good flexibility and chemical resistance, making them suitable for interior walls and standard exterior walls. However, their weather resistance is relatively weak.

Fluorocarbon Coating (PVDF Coating)

Fluorocarbon coatings are highly weather-resistant, capable of maintaining color stability for extended periods. They are more expensive and are typically used for high-end buildings or harsh environments.

Acrylic Coating

Acrylic coatings are characterized by high transparency and gloss, but they fall slightly short in corrosion and weather resistance. These coatings are ideal for cost-sensitive projects.

Epoxy Coating

Epoxy coatings provide excellent adhesion and chemical resistance, making them suitable for industrial applications requiring high-strength protection. However, they are not ideal for long-term outdoor use due to poor UV resistance.

We can use the following icons to get a clear and concise picture of the service life and age of the various paints and prices.

Composition of Coatings and Their Impact on Performance

Key Components of Coatings

1. Resins:

Define the matrix and properties of the coating, e.g., polyester resin for flexibility, fluorocarbon resin for weather resistance.

2. Pigments:

Provide color and gloss while influencing lightfastness and durability.

3. Additives:

Enhance functionality, such as improving adhesion and UV resistance.

Key Performance Indicators of Coatings

· Weather Resistance:

Fluorocarbon coatings perform best for long-term outdoor use.

· Adhesion:

Determines the coating's stability on the aluminum surface.

· Gloss and Color Stability:

Essential for the aesthetic appeal of architectural projects.

The Impact of Coating Quality on the Lifespan of Color-Coated Aluminum Coils

Performance Comparison of Different Coatings

· Polyester Coating:

Economical but with a shorter lifespan, suitable for short-term projects.

· Fluorocarbon Coating:

Higher cost but provides the best anti-aging performance and long-term color retention.

· Acrylic Coating:

Cost-effective, fitting for projects with budget constraints.

· Epoxy Coating:

Offers high-strength protection, ideal for industrial use.

Relationship Between Coating Thickness and Service Life

Coatings that are too thin may fail to provide adequate protection, while overly thick coatings increase costs and may lead to cracking.

Environmental Impact on Coating Performance

Harsh environmental conditions, such as high humidity or acid rain, accelerate coating degradation, making weather-resistant coatings a crucial choice.

Coating Application Processes and Their Impact on Quality

Key Steps in the Coating Process

1. Surface Preparation:

Cleaning the aluminum surface to enhance coating adhesion.

2. Coating Application:

Using advanced equipment to ensure uniform application.

Control of Coating Thickness and Uniformity

A uniform coating thickness maximizes protection while avoiding material wastage.

How to Choose the Right Coating Type?

Recommendations Based on Budget

· Low Budget:

Opt for polyester or acrylic coatings.

· High Budget:

Choose fluorocarbon coatings for extended service life.

Recommendations Based on Usage Environment

· Harsh Outdoor Conditions:

Fluorocarbon coatings are the best option.

· Indoor Applications:

Polyester coatings are more economical and practical.

Conclusion and Suggestions

When choosing aluminum coil coatings, it is crucial to consider the usage environment, budget, and expected service life. Selecting the right coating material based on specific needs can significantly enhance the performance and value of aluminum coils.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg