Anodized Aluminum vs Stainless Steel: Which Material Is Better?

1. Appearance

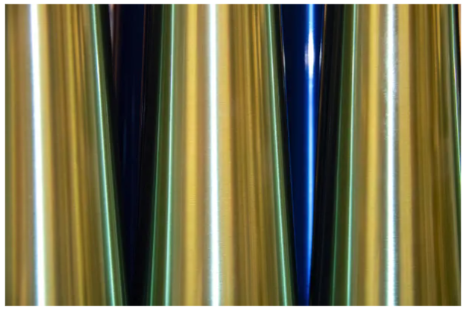

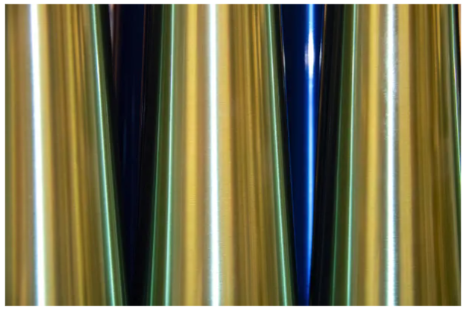

Anodized Aluminum

Anodized aluminum has a wide range of colors available. The anodizing process creates a porous oxide layer on the surface of the aluminum, which can be dyed to achieve various hues. This makes it a popular choice for decorative applications such as architectural facades, consumer electronics casings (like some smartphones and laptops), and interior design elements.

The finish of anodized aluminum can range from a matte to a high - gloss look. The smooth and even appearance gives it an aesthetically pleasing quality. For example, in modern architecture, anodized aluminum panels can provide a sleek and contemporary look to buildings.

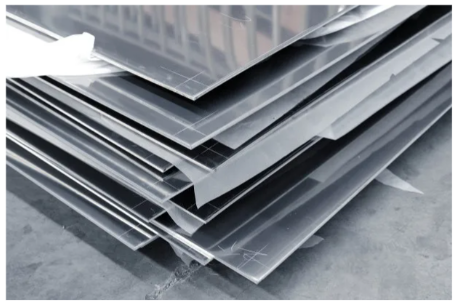

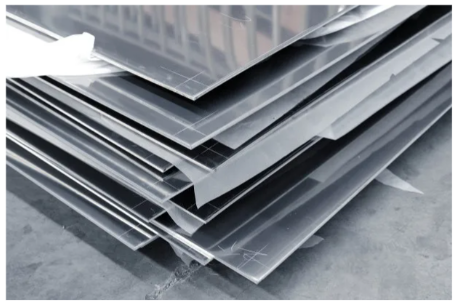

Stainless Steel

Stainless steel has a natural, metallic luster that is often associated with a sense of durability and strength. It comes in different surface finishes such as brushed, polished, or satin. The brushed finish gives a directional texture, while the polished finish provides a mirror - like shine.

It has a more industrial or classic appearance and is commonly used in applications where a tough and reliable look is desired. For instance, in kitchen appliances, stainless - steel surfaces convey a sense of hygiene and robustness.

2. Corrosion Resistance

Anodized Aluminum

The anodized layer on aluminum acts as a protective barrier against corrosion. It is highly resistant to atmospheric corrosion, which makes it suitable for outdoor applications such as outdoor furniture, signage, and window frames.

However, in some harsh chemical environments, the anodized layer may be damaged over time. For example, exposure to strong acids or alkalis can cause the anodized coating to deteriorate. But in normal environmental conditions like rain, snow, and sunlight, it can maintain its integrity for a long time.

Stainless Steel

Stainless steel contains chromium, which forms a passive oxide layer on its surface that provides excellent corrosion resistance. It can withstand a wide range of corrosive substances, including water, many chemicals, and even some mild acids.

It is a preferred material for applications in the food and beverage industry, chemical processing plants, and marine environments (such as boat fittings and equipment) due to its ability to resist corrosion even in relatively harsh conditions.

| Comparison Items | Anodized Aluminum | Stainless Steel |

| Appearance | - Offers a wide range of colors through the anodizing process.

- Can have a matte to high - gloss finish, providing a sleek and modern look. | - Has a natural metallic luster.

- Comes in different finishes such as brushed, polished, or satin, with an industrial or classic appearance. |

| Corrosion Resistance | - The anodized layer provides good resistance to atmospheric corrosion, suitable for outdoor use.

- May be damaged in harsh chemical environments. | - The chromium - containing passive oxide layer offers excellent resistance to a wide range of corrosive substances, including chemicals and mild acids.

- Ideal for food, chemical, and marine applications. |

| Strength and Durability | - Good strength depending on alloy and manufacturing, suitable for lightweight structural applications.

- Generally not as strong as stainless steel and may deform under heavy loads or impacts. | - Known for high strength and durability, can withstand heavy loads and mechanical stresses.

- Different grades offer different strength levels for various applications. |

| Cost | - Generally less expensive due to lower raw material cost and cost - effective anodizing process.

- More affordable for large - scale applications and replacements. | - More expensive because of higher raw material and complex manufacturing costs.

- Cost varies depending on grade and application requirements. |

| Thermal Conductivity | - Excellent heat conductor; anodized layer doesn't significantly affect it, good for heat transfer applications. | - Has a lower thermal conductivity; may not be as efficient for rapid heat transfer, but can be an advantage for insulation. |

| Weight | - Lightweight, easy to handle, transport, and install.

- Reduces overall weight in aerospace and automotive applications. | - Relatively heavy; can be a disadvantage in weight - critical applications but an advantage for stability and mass - required uses. |

3. Strength and Durability

Anodized Aluminum

While aluminum itself is a lightweight material, anodized aluminum can have good strength depending on its alloy composition and the manufacturing process. It can be used for structural applications such as in the construction of lightweight frames for vehicles, aircraft interiors, and some building components.

However, it is generally not as strong as stainless steel. In applications where high - impact resistance or heavy - duty strength is required, anodized aluminum may not be the best choice. For example, in machinery parts that are subject to heavy loads or frequent impacts, it may deform more easily than stainless steel.

Stainless Steel

Stainless steel is known for its high strength and durability. It can withstand heavy loads, high - pressure environments, and mechanical stresses. Different grades of stainless steel offer different levels of strength. For example, austenitic stainless steels have good ductility and are suitable for applications where some deformation is allowed, while martensitic stainless steels are harder and more suitable for applications requiring high strength and wear resistance.

4. Cost

Anodized Aluminum

Anodized aluminum is generally less expensive than stainless steel. The raw material cost of aluminum is lower than that of stainless steel, and the anodizing process is relatively cost - effective. This makes it a more affordable option for large - scale applications such as building exteriors and consumer products.

The lower cost also allows for more flexibility in design and replacement. If a component made of anodized aluminum is damaged or needs to be updated, the cost of replacement is usually lower than that of a comparable stainless - steel component.

Stainless Steel

Stainless steel is more expensive due to the higher cost of raw materials and more complex manufacturing processes. The extraction and refining of the metals used in stainless steel (such as chromium, nickel, and molybdenum) are more costly.

The cost of stainless steel can vary significantly depending on the grade and the specific requirements of the application. High - performance grades with enhanced corrosion resistance and strength can be quite pricey.

5. Thermal Conductivity

Anodized Aluminum

Aluminum is an excellent conductor of heat. The anodized layer does not significantly affect its thermal conductivity. This makes anodized aluminum a good choice for applications where heat transfer is important, such as in heat sinks for electronics.

In cooling systems, anodized aluminum can efficiently dissipate heat, helping to maintain the proper operating temperature of components. For example, in computer CPUs, anodized aluminum heat sinks are commonly used to prevent overheating.

Stainless Steel

Stainless steel has a lower thermal conductivity compared to aluminum. In applications where rapid heat transfer is a key requirement, stainless steel may not be as efficient. However, in some cases where insulation or slow heat transfer is desired, such as in some heat - resistant containers or equipment, stainless steel's lower thermal conductivity can be an advantage.

6. Weight

Anodized Aluminum

One of the major advantages of anodized aluminum is its light weight. This makes it easy to handle, transport, and install. In applications such as aerospace and automotive industries, the lightweight nature of anodized aluminum helps to reduce overall weight, which in turn can lead to better fuel efficiency (in vehicles) or reduced payload requirements (in aircraft).

For example, in the construction of aircraft interiors, anodized aluminum panels are used to keep the weight of the cabin structure to a minimum while still providing the necessary functionality and aesthetics.

Stainless Steel

Stainless steel is a relatively heavy material. This can be a disadvantage in applications where weight is a critical factor. However, in some cases where stability and mass are required, such as in heavy - duty machinery bases or structural supports in buildings, the weight of stainless steel can be an advantage.

| Material | Density (g/cm³) | Dimensions (Length × Width × Thickness) | Weight (kg) |

| Anodized Aluminum | 2.71 | 1m × 1m × 1mm | 2.71 |

| 304 Stainless Steel | 7.93 | 1m × 1m × 1mm | 7.93 |

| 316 Stainless Steel | 8.03 | 1m × 1m × 1mm | 8.03 |

In conclusion, the choice between anodized aluminum and stainless steel depends on the specific requirements of the application. If cost - effectiveness, a wide range of colors, and lightweight are important factors, anodized aluminum may be the better choice. On the other hand, if high strength, excellent corrosion resistance in harsh environments, and a classic metallic look are desired, stainless steel is likely to be more suitable.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg