-

A Aluminum trim coil and Channel letter aluminum coil are both made of aluminum alloy, but their shapes and uses are different.

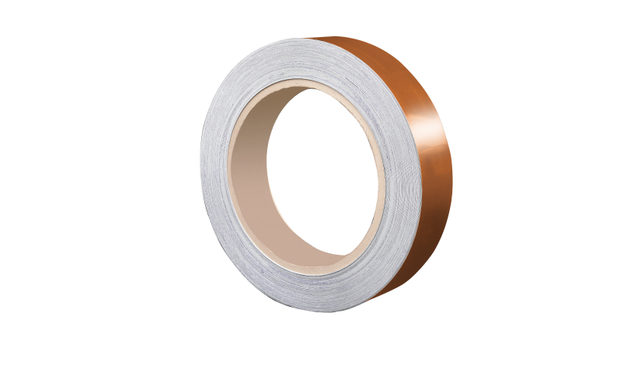

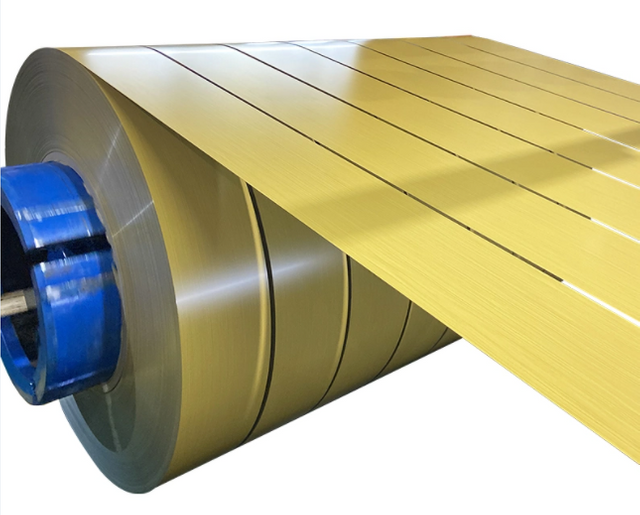

Aluminum trim coil is a kind of aluminum strip material processed into specific shapes. It is usually made of high-quality aluminum alloy and has good tensile strength, corrosion resistance, high temperature resistance and other characteristics. The surface treatment of aluminum trim coil can be anodizing, electrophoresis painting, sandblasting and other processes, and can be processed into various shapes and sizes according to different needs. It is mainly used for car body decoration, building decoration and other occasions.

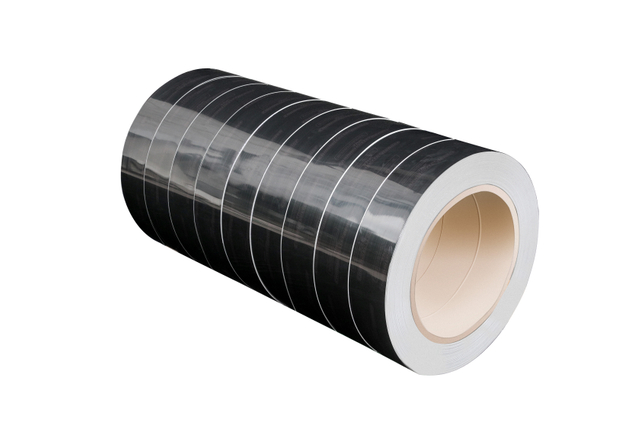

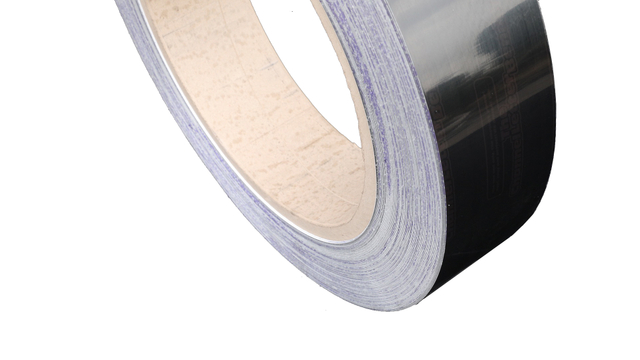

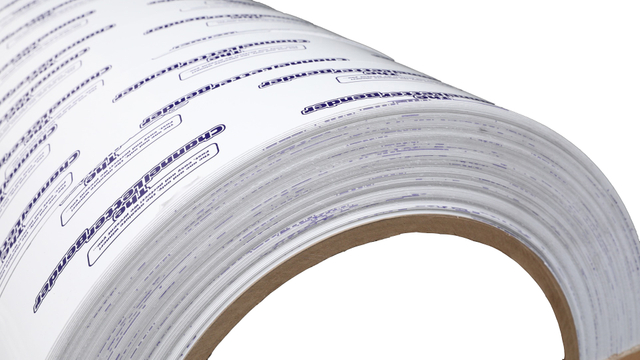

Channel letter aluminum coil is a kind of aluminum strip material processed into channel letter shape, which is also made of high-quality aluminum alloy and has good tensile strength, corrosion resistance, high temperature resistance and other characteristics. Channel letter aluminum coil is processed into channel letter shape through cutting, bending, welding, surface treatment and other processes, with high dimensional accuracy and good appearance quality. It is mainly used for outdoor advertising, building decoration and theme park decoration and other occasions. Channel letter aluminum coil can also be processed into various shapes and sizes according to customer requirements.

Therefore, the difference between aluminum trim coil and Channel letter aluminum coil is the processing process and shape after processing, but their materials and properties are similar.

-

A There are several methods to save the retains of the channel letter aluminum coil left in stock, as follows:

Cleanliness: Clean the surface of the channel letter aluminum coil in stock, clean the dirt and impurities on the surface, and prevent rust and corrosion.

Separation: Separate the channel letter aluminum coil according to different grades, specifications and colors. Avoid mixing different grades, specifications and colors together, which will cause unnecessary trouble in later use.

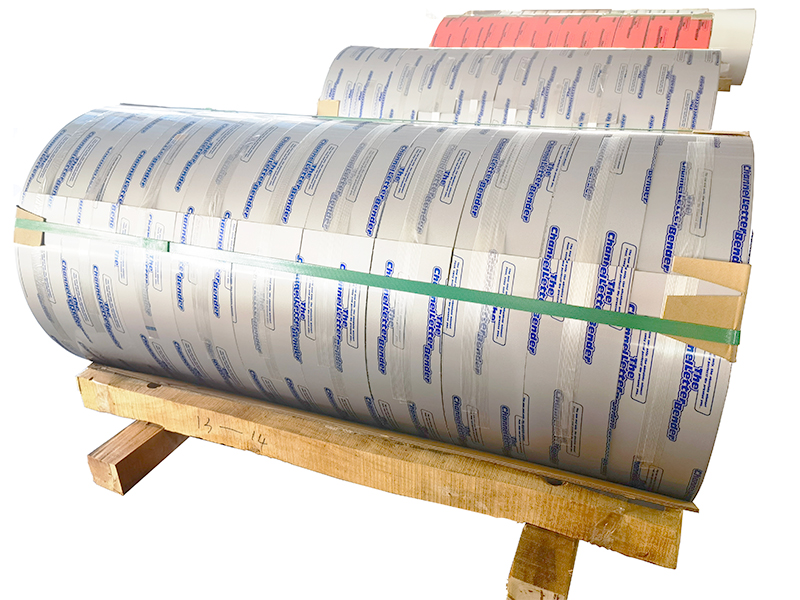

Storage Method: The channel letter aluminum coil should be stored in a cool and dry place. If stored in the open air for a long time, it may cause rust and corrosion. It is recommended to store it in a warehouse or shed with good sealing performance to avoid moisture and rainwater.

Stacking Method: Stack the channel letter aluminum coil neatly to avoid deformation or damage due to collision or pressure. It is recommended to stack it on wooden pallets or tables, and use wooden braces to support the corners to prevent rolling and sliding.

Surface Protection: If the surface of the channel letter aluminum coil is painted or treated, it should be protected to avoid damage to the surface during storage. It is recommended to wrap the surface with plastic film or other protective materials.

Regular Inspection: Regularly inspect the channel letter aluminum coil stored in stock, check whether there is rust, corrosion or other damage, and take corresponding measures in time.

Proper Packaging: If there are orders for the channel letter aluminum coil in stock, it should be packaged properly according to the requirements of customers. The packaging materials should be moisture-proof, moisture-proof and wear-resistant, and marked with the name, quantity and other relevant information of the goods.

In short, in order to save the retains of the channel letter aluminum coil left in stock, it is necessary to maintain cleanliness, separate different grades, specifications and colors, store it in a cool and dry place, stack it neatly, protect the surface and regular inspection. In addition, appropriate packaging should also be carried out according to customer requirements.

-

A To cut and bend the channel letter aluminum coil, the following steps should be followed:

Precision cutting: use precision cutting machine to cut the channel letter aluminum coil into the length and quantity needed according to the specific requirements. The minimum curvature radius of the channel letter aluminum coil is about 10mm. The accuracy requirements are very high, and it needs to ensure that the cut edge is vertical and smooth, and the burr and shearing force must be zero.

Surface treatment: the cut end face of the channel letter aluminum coil needs to be surface treated, so as to maintain its beautiful appearance and enhance its service life. The surface treatment methods include anodizing, electrophoresis painting, sandblasting, etc., which can be selected according to different requirements.

Bending process: use bending machine to bend the channel letter aluminum coil into different shapes and angles according to the specific requirements. The bending radius should be large enough to avoid too much stress and deformation of the material. The bending angle should be accurate enough to ensure that the installation accuracy is high.

Assembly and installation: after the bending process is completed, it needs to be connected with brackets or clips to complete the installation. The brackets or clips should be fixed accurately according to the specific requirements, and the installation accuracy should be high enough to ensure that the appearance of the installation effect is beautiful.

In short, the process of cutting and bending the channel letter aluminum coil requires high accuracy and precision, which requires operators to have a certain level of technology and experience. If there is no professional operation skills, it is recommended to seek help from professionals or professionals.

-

A it cannot be used, please contact the seller for return or exchange or other remedies.

-

A If you need the same color one both side, you can order it with the same color, it can be different color as your order’s request.

-

A It can be customized for the thickness,width,length or even weight of each coil.

-

A For the PE coating of aluminum trim coil, the warranty can be 8-15 years.

But for the PVDF coating of aluminum trim coi, the warrantry can be 25-30 years.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg

GENERAL PARAMETERS

GENERAL PARAMETERS