Color Coating Aluminum Used For Capacitor Shell

The below aluminum alloys are always used for Capacitor Shell.Alloy 1050 1060 1100 and 3004.Due to the aluminum alloy have the quite many advantages such as light weight,excellent electrical conductivity also thermal conductivity,great mechanical properties and corrosion resistance.The superiority make the above aluminum alloys widely used as material for manufacturing capacitor shells electronic products,automotive electronics,industrial applications,communication equipments,energy fields and etc.

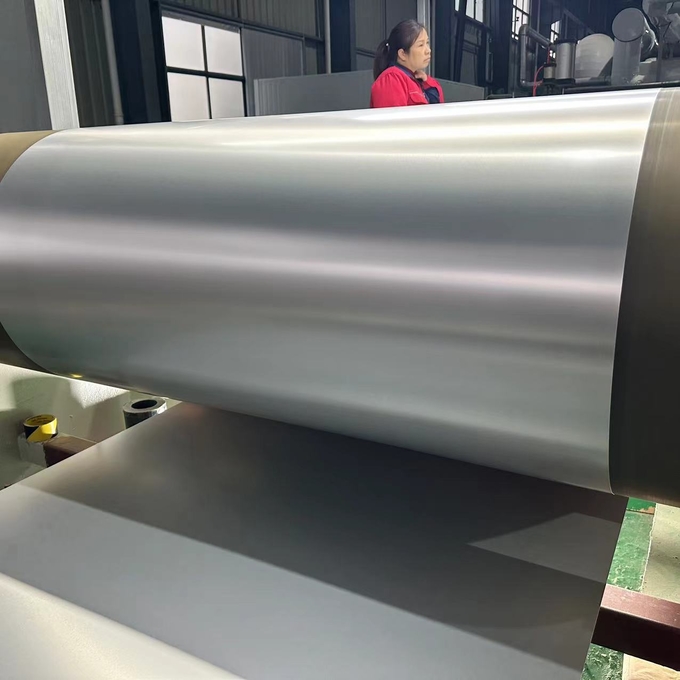

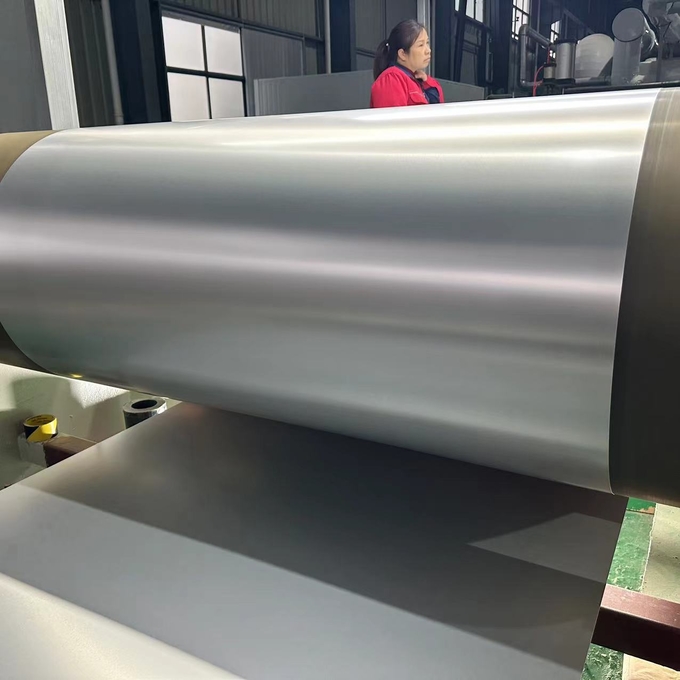

Among of that,color coating aluminum is the better option for the Capacitor Shell Manufacturing.

The correctest option to choose Dingang Painted Aluminum Alloy For Your Electrical Capacity Manufacturing.

Dingang's painted aluminum quality control can completely meet the strict quality standard such as GB,EN,ASTM,BS and AMS etc.

We are proud to say that our production and management teams comply with the highest quality system for aluminum and aluminum alloy strips used in capacitor shells. Thanks to their expertise, we can guarantee that our products have excellent electrical conductivity, thermal conductivity, and mechanical properties. They are also highly resistant to corrosion and have impressive strength.

The Specs of Aluminium and aluminum alloy strip for capacitor shell

| Alloy | Temper | Specs |

| Thickness | Width | Inner ID |

| 1050, 1060, 1070 | O | 0.26-0.50 | 300.0-600.0 | 150, 200, 300 |

| 1100 | H12, H22, H14, H24, O | 0.26-0.50 | 300.0-600.0 | 150, 200, 300 |

| 3004 | O | 0.26-0.50 | 300.0-600.0 | 150, 200, 300 |

| Strip thickness tolerance | +0.02 mm /0 mm |

| Width Tolerance (Normal Grade) | ±1.0mm |

| Width Tolerance (High Precision) | ±0.5mm |

The chemical composition of aluminum and aluminum alloy strips used for capacitor case

| Element | Composition (%) |

| 1050 | 1060 | 1070 | 1100 | 3004 |

| Si | 0.25 | 0.25 | 0.2 | Si+ Fe 0.95 | 0.3 |

| Fe | 0.4 | 0.35 | 0.25 | 0.7 |

| Cu | 0.05 | 0.05 | 0.04 | 0.05-0.2 | 0.25 |

| Mn | 0.05 | 0.03 | 0.03 | 0.05 | 1-1.5 |

| Mg | 0.05 | 0.03 | 0.03 | - | 0.8-1.3 |

| Cr | - | - | - | - | - |

| Ni | - | - | - | - | - |

| Zn | 0.05 | 0.05 | 0.04 | 0.1 | 0.25 |

| V | 0.05 | 0.05 | 0.05 | - | - |

| Ti | 0.03 | 0.03 | 0.03 | - | - |

| Zr | - | - | - | - | - |

| Other | single | 0.03 | 0.03 | 0.03 | 0.05 | 0.05 |

| total | - | - | - | 0.15 | 0.15 |

| AL | 99.5 | 99.6 | 99.7 | 99 | Remainder |

The mechanical properties of Aluminium and aluminum alloy strip for capacitor shell

| Alloy | Temper | Thickness/mm | Tensile Strength /(N/mm2) | Elongation /% |

| 1050, 1060, 1070 | O | 0.26-0.50 | 70-90 | ≥25 |

| 1100 | O | 0.26-0.50 | 70-100 | 25 |

| H12, H22 | 0.26-0.50 | 100-120 | 5.0 |

| H14, H24 | 0.26-0.50 | 120-145 | 2.0 |

| 3004 | O | 0.26-0.50 | 175-200 | 15 |

The ear rate of aluminium strip for capacitor shell

| Alloy | Temper | Ear rate/% |

| Ordinary | High precision |

| 1050, 1060, 1070 | O | 6.0 | 5.0 |

| 1100 | O | 6.0 | 5.0 |

| H12, H22 | 6.0 | 5.0 |

| H14, H24 | 5.0 | 3.0 |

| 3004 | O | 5.0 | 3.0 |

The Properties Of Aluminum For Capacitor Shell

-Light Weight

The aluminum strip used for capacitor shells is lightweight, which is an important characteristic for this application. The lower density of aluminum and aluminum alloy strips allows for a significant reduction in the weight of the capacitor case. This is an invaluable advantage for electronic devices and applications that require a lightweight design, including mobile devices, aerospace devices, and more.

-Excellent Conductivity

Aluminum offers excellent conductivity, making it an ideal material for a variety of applications. Aluminum is an excellent conductor with low electrical resistance and high conductivity. The use of aluminum and aluminum alloy strips to make capacitor shells provides good current transmission and connection performance, which is beneficial to the performance of capacitors.

Aluminum and aluminum alloy strips offer excellent thermal conductivity, which is beneficial for a variety of applications. Aluminum and aluminum alloy strips have excellent thermal conductivity, enabling effective heat transfer and dissipation. This is a crucial advantage for some capacitors in high-power or high-temperature environments, as it helps to reduce temperature and enhance the stability and lifespan of the device.

-Excellent Corrosion Resistance

Aluminum offers excellent corrosion resistance. Aluminum and aluminum alloy strips are highly corrosion-resistant, capable of resisting oxidation, acid and alkali, and other forms of environmental erosion. The capacitor casing, made of aluminum and aluminum alloy strips, is designed to withstand the rigors of various working environments, ensuring a long service life.

-High Tensile Strength

Aluminium materials offers high tensile strength, which is an important quality for many industrial applications. Aluminum and aluminum alloy strips are capable of withstanding a range of physical and mechanical stresses due to their relatively high strength. This ensures that the capacitor case remains stable and structurally sound under varying operating conditions.

-Easy to process and form

Aluminum and aluminum alloy strips are convenient to process and form, and can be produced by calendering, shearing, stamping, and other methods. This makes the production process of capacitor housings more flexible and efficient, enabling the creation of products in a variety of shapes and sizes.

Quick Quote Aluminum and aluminum alloy strips can be reliably connected to other materials or components by welding, riveting, or other means. This facilitates a robust connection and optimal electrical conductivity between the capacitor case and internal components.

The product boasts an appealing appearance and surface treatment performance. Aluminum and aluminum alloy strips can be decorated and protected through anodizing, spraying, coating, and other surface treatment methods. This not only provides an aesthetically pleasing case, but also increases the durability and oxidation resistance of the capacitor, offering a more robust and reliable product.

The application of aluminum strips used for capacitor case

-Electronic products:

Aluminum and aluminum alloy strips are used to make capacitor shells and are widely used in various electronic products. For example, electrolytic capacitors and solid electrolytic capacitors in consumer electronics products such as mobile phones, tablet computers, notebook computers, and televisions often use aluminum and aluminum alloy strips as casing materials.

-Communication equipment:

In the field of communication equipment, such as base stations, communication terminals, etc., the capacitor shell is made of aluminum and aluminum alloy strips to provide a lightweight, high-strength shell structure, and at the same time have good electrical conductivity and thermal conductivity to ensure the stability of the equipment and efficient operation.

-Automotive electronics:

With the development of automotive electronics technology, capacitors are more and more widely used in automobiles. Aluminum and aluminum alloy strips are used to make capacitor casings, which can meet the requirements of lightweight, high strength and corrosion resistance for automotive electronic products, such as automotive battery management systems, power electronic modules, etc.

-Energy field:

In the energy field, aluminum and aluminum alloy strips are widely used in the manufacture of casings for power capacitors and energy storage devices. These devices need to have efficient current transmission and heat dissipation capabilities, and have high requirements for structural stability and corrosion resistance.

-Industrial application:

Capacitor shells made of aluminum and aluminum alloy strips are also suitable for various electrical equipment, motors, frequency converters, etc. in the industrial field. Its excellent conductivity and heat dissipation performance enable it to meet the requirements of industrial equipment for capacitors in high-power and high-temperature environments.

Dingang's painted coating aluminum sheet is definately your good choice in the electricial production area.

For know more about our paint coated aluminum product,here's Dingang's PVDF painted aluminum product introduction.

Changzhou Dingang Metal Material Co.,Ltd

Robert Tang

Email: robert@cnchangsong.com

Phone: + 0086 159 6120 6328 (whatsapp / wechat)

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg