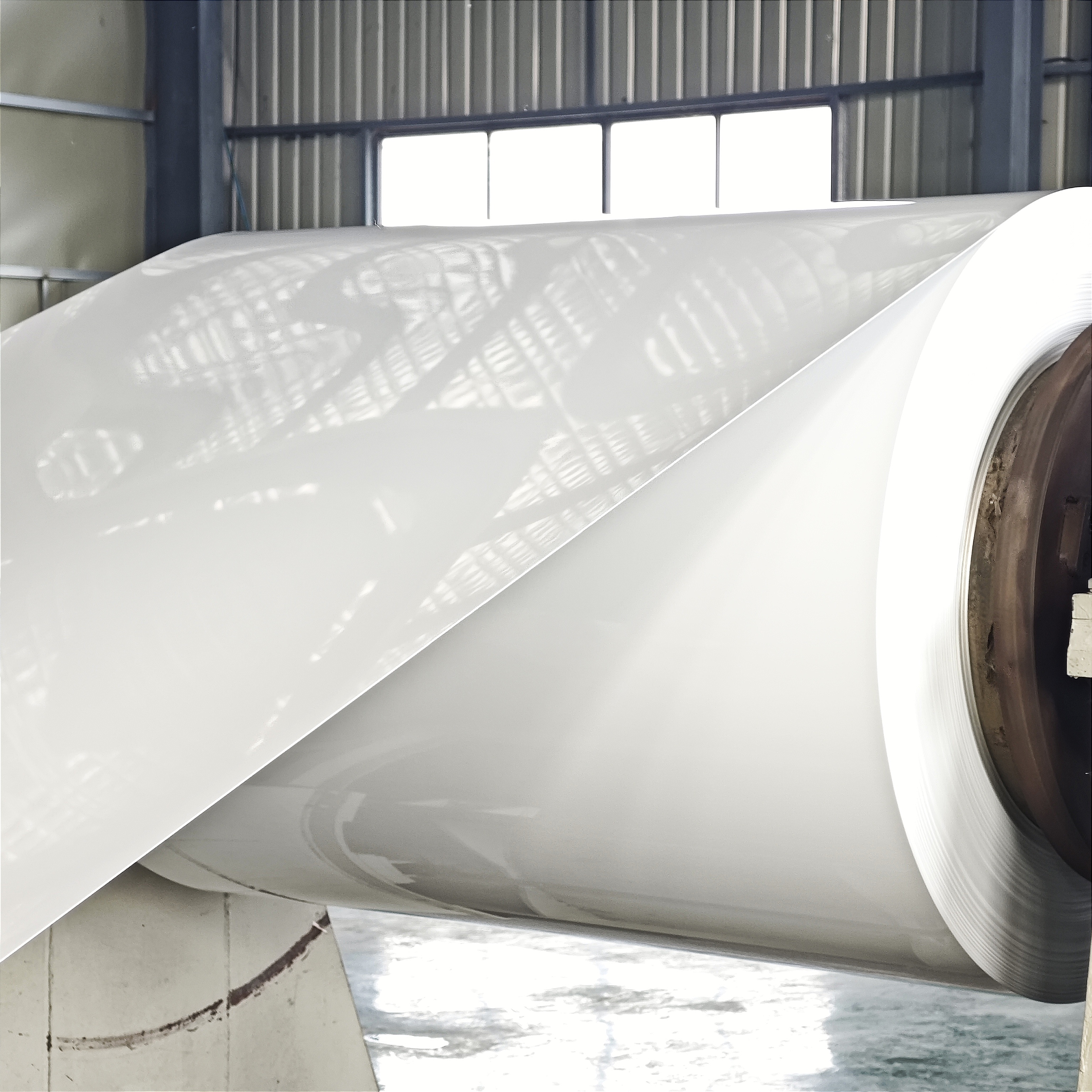

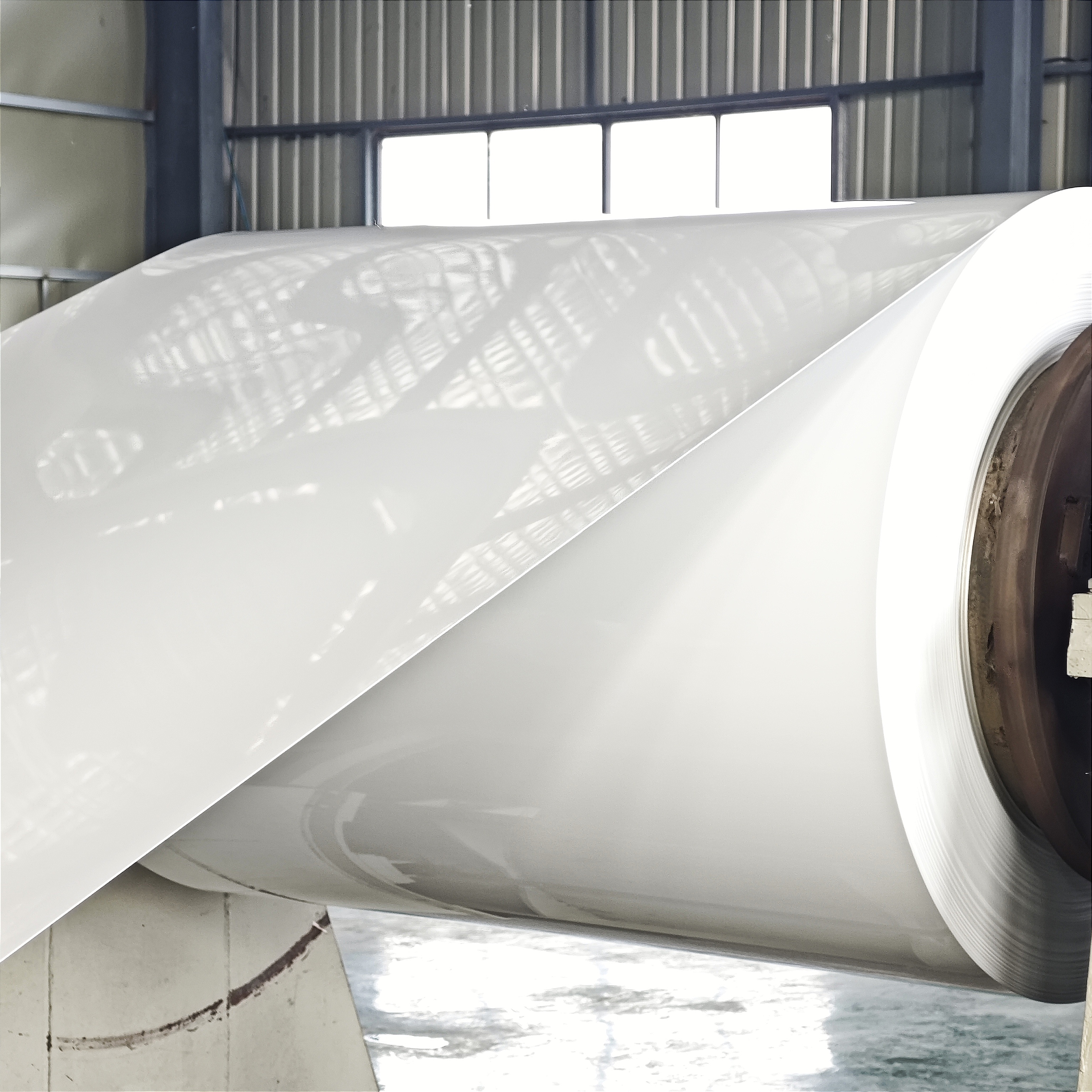

Colored Aluminum Plates: A Versatile and Durable Solution

Colored aluminum plates, also known as pre - painted aluminum sheets, are a popular choice in various industries. They are made by coating high - grade aluminum substrates with one or more layers of organic paint, resulting in a product that combines the benefits of aluminum with the aesthetic and protective qualities of the coating.

Physical and Mechanical Properties

Colored aluminum plates are available in a wide range of thicknesses, typically from 0.15 mm to 4 mm, with widths spanning from 200 mm to 2000 mm. They can be produced in different alloy series such as 1000, 2000, 3000, 4000, 5000, and 6000 series, each offering unique properties. For example, the 1000 series, mainly pure aluminum, provides excellent corrosion resistance and formability. The 5000 series, an aluminum - magnesium alloy, offers good strength and enhanced corrosion resistance, especially in marine environments.

| Alloy Series | Main Characteristics | Common Applications in Colored Plates |

| 1000 | High purity, excellent corrosion resistance, good formability | General - purpose applications, decorative items where formability is key |

| 3000 | Aluminum - manganese alloy, good workability, moderate strength | Construction for roofing and siding, general sheet metal work |

| 5000 | Aluminum - magnesium alloy, high strength, very good corrosion resistance | Marine applications, automotive parts, structures in corrosive environments |

The paint coatings used on these plates are usually either polyester (PE) or polyvinylidene fluoride (PVDF). PE - coated plates are more cost - effective and suitable for general - use applications. They offer a good range of colors based on the RAL color card. PVDF - coated plates, on the other hand, are more expensive but provide superior durability, weather resistance, and colorfastness. The paint coating thickness typically ranges from 10 - 60 μm, with coating styles like 2/1 (two - coat, one - bake) or 2/2 (two - coat, two - bake).

Applications

Construction

In the construction industry, colored aluminum plates are extremely versatile. They are used for exterior wall decoration, providing an attractive and durable finish. Their weather resistance ensures that they can withstand various climate conditions, including wind, rain, and temperature fluctuations, without bending, deforming, or fading. For example, in commercial buildings, colored aluminum curtain walls not only enhance the building's aesthetic appeal but also offer long - term protection. They are also used for roof panels, where their light weight reduces the structural load. In residential construction, they can be found in partitions, ceilings, and even as insulation boards due to their low light absorption and heat insulation properties.

Transportation

Colored aluminum plates are used in the transportation sector, particularly in the interiors and exteriors of vehicles. In the automotive industry, they are used for car interiors, such as door panels and dashboard components, providing a lightweight yet durable solution. For trains and airplanes, colored aluminum sheets are used for interior trims, luggage compartments, and sometimes even for external body parts. Their corrosion resistance is especially important in marine transportation, where they are used for ship interiors and some exterior fittings.

Home Appliance Manufacturing

Home appliance manufacturers often use colored aluminum plates for making appliance shells and internal components. For instance, in refrigerators and air conditioners, these plates offer a combination of light weight, corrosion resistance, and easy formability. They can be easily shaped into the required designs, and their attractive appearance enhances the overall look of the appliances.

Packaging Industry

In the packaging of food and beverages, colored aluminum plates are utilized for their good sealing and preservation properties. They protect products from external environmental factors such as moisture and oxygen, helping to extend the shelf life of the products. Additionally, their light weight makes them a cost - effective option for transportation, reducing fuel consumption.

Selection Considerations

When choosing colored aluminum plates, several factors need to be considered. Thickness selection depends on the application. Thinner sheets are suitable for decorative purposes, while thicker ones are required for applications that need to bear weight. Paint selection is crucial; if long - term durability and weather resistance are essential, PVDF - coated plates are a better choice, despite the higher cost. The color and pattern should be chosen according to the use environment and personal preferences, while ensuring color durability. Also, the surface flatness of high - quality plates should be smooth, free of bubbles and impurities. Finally, selecting a reliable manufacturer is important, considering factors such as their qualifications, production experience, and product testing procedures.

In conclusion, colored aluminum plates are a highly versatile and durable material, suitable for a wide range of applications. Their combination of mechanical properties, corrosion resistance, and aesthetic appeal makes them a preferred choice in many industries.

Contact us to know more about painted aluminum coil / aluminum sheet /aluminum strip / aluminum circle.

Changzhou Dingang Metal Material Co.,Ltd

www.cnchangsong.com

www.prepaintedaluminium.com

Robert Tang ( Sales Representative )

Email: robert@cnchangsong.com

Phone: 0086 159 6120 6328 ( whatsapp & wechat)

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg