What is an anodized aluminum roll?

The basic principles of anodic oxidation

Anodized aluminum coil production is a process of generating oxide film on the surface of aluminum by electrochemical reaction. This process can not only significantly improve the corrosion resistance, hardness and decoration of aluminum, but also can give it good insulation performance and longer service life. The following is the basic principle of anodic aluminum oxide coil production step by step analysis:

1. Preparation of the aluminum substrate

Before the anodic oxidation begins, the aluminum rolls shall be cleaned and processed.

unoil:

Use chemical or mechanical methods to remove grease and dirt from the aluminum surface to ensure the uniformity of the oxide film.

scouring:

Oxides and impurities on the surface are removed by a dilute acid solution, exposing the pure metal surface.

neutralization:

Use alkaline solution to neutralize the residual acid after pickling to ensure that the surface is clean and free.

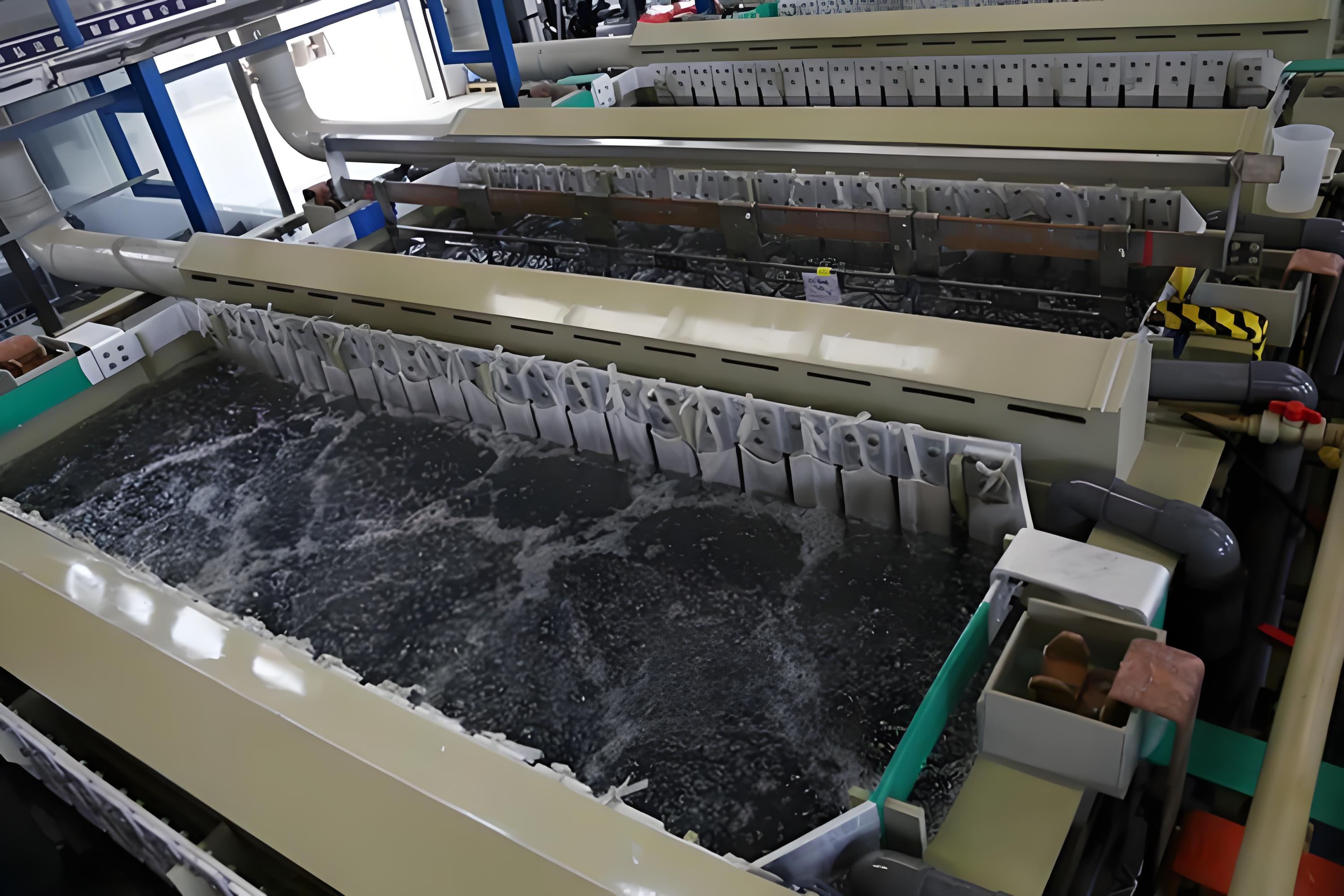

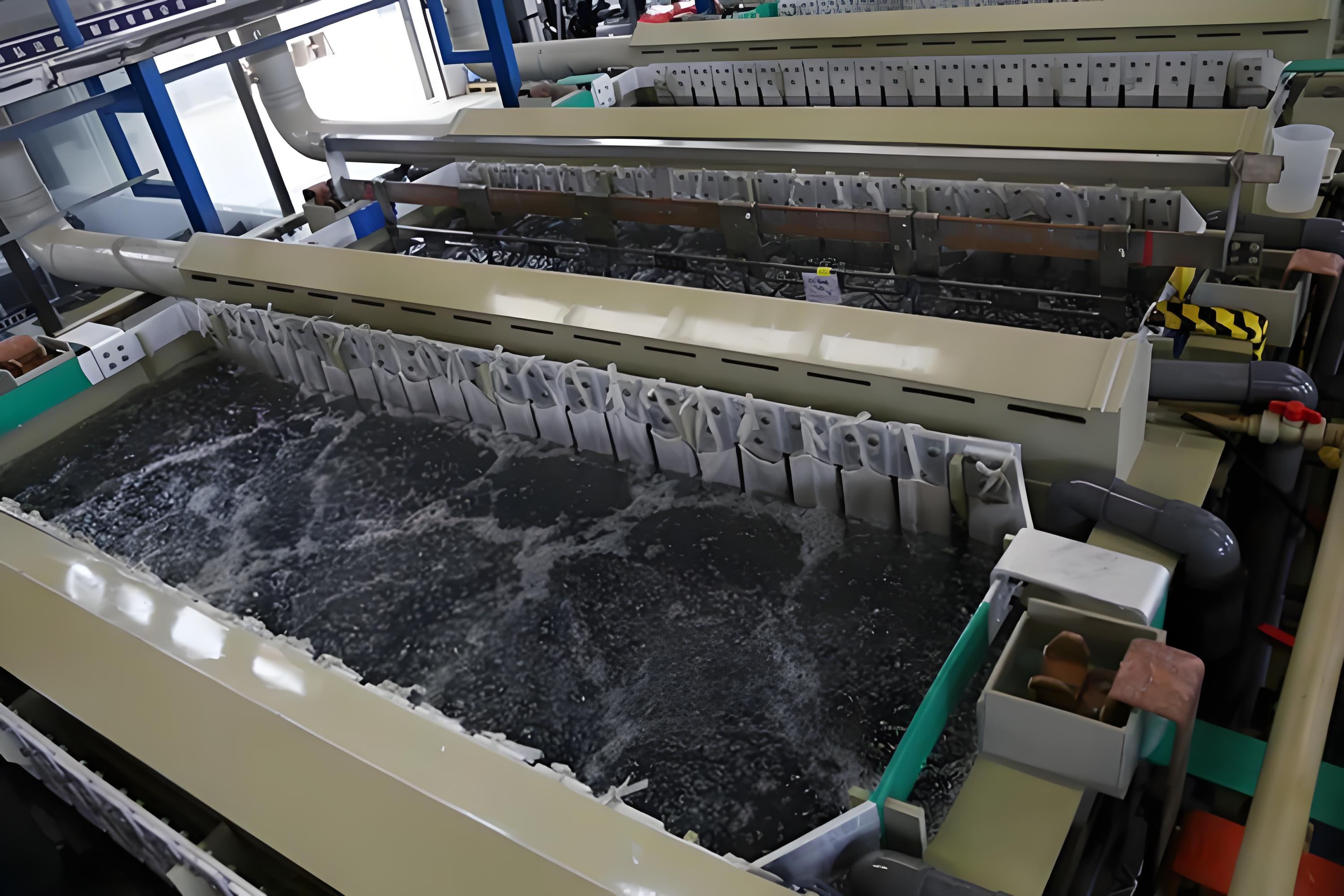

2. Configuration of the electrolytic cell

The electrolytic cell is the core equipment of the anodizing process, and its configuration is as follows:

electrolyte:

Usually sulfuric acid solution, phosphoric acid, oxalic acid or chromic acid solution can also be used as required. Sulfuric acid solutions are widely used because of their low cost and high efficiency.

direct-current main:

The aluminum coil is connected to the anode, and the conductive material (such as lead or stainless steel) is used as the cathode to complete the electrolytic reaction through direct current.

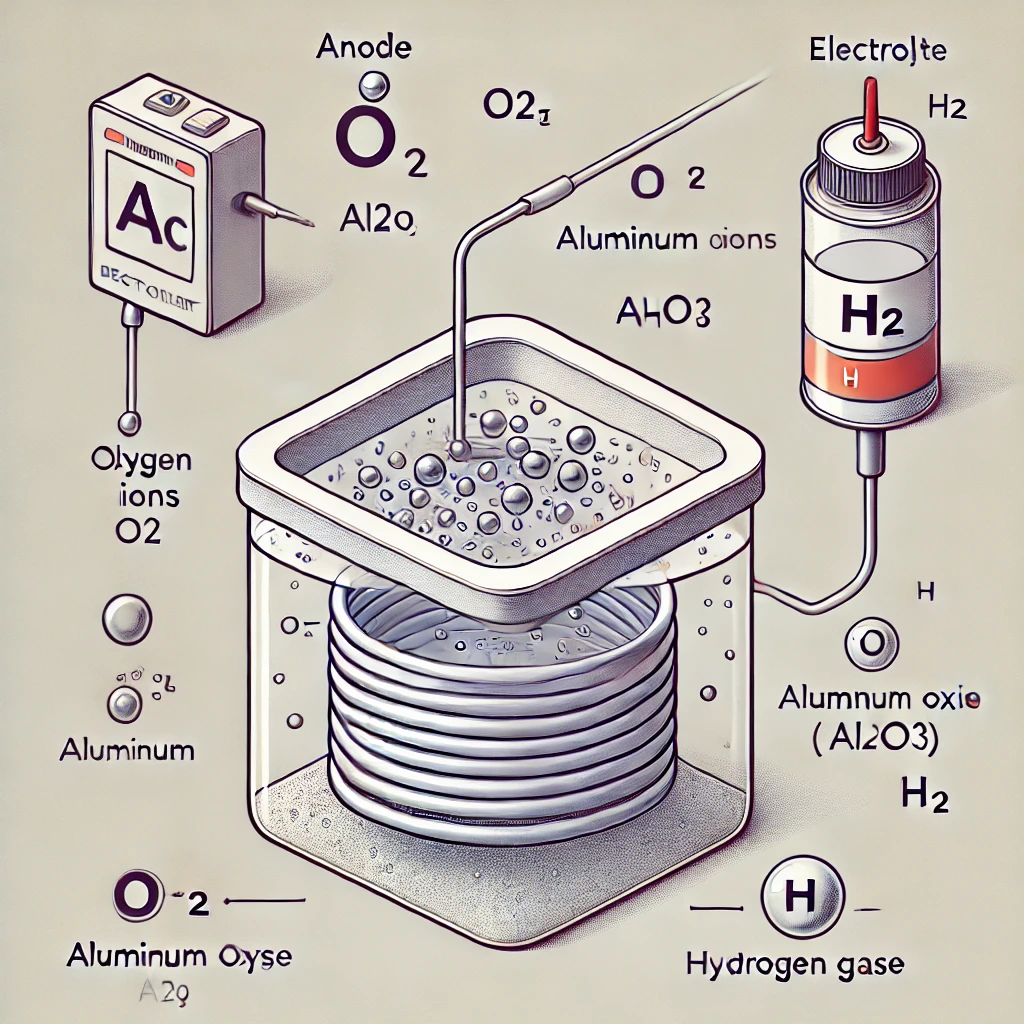

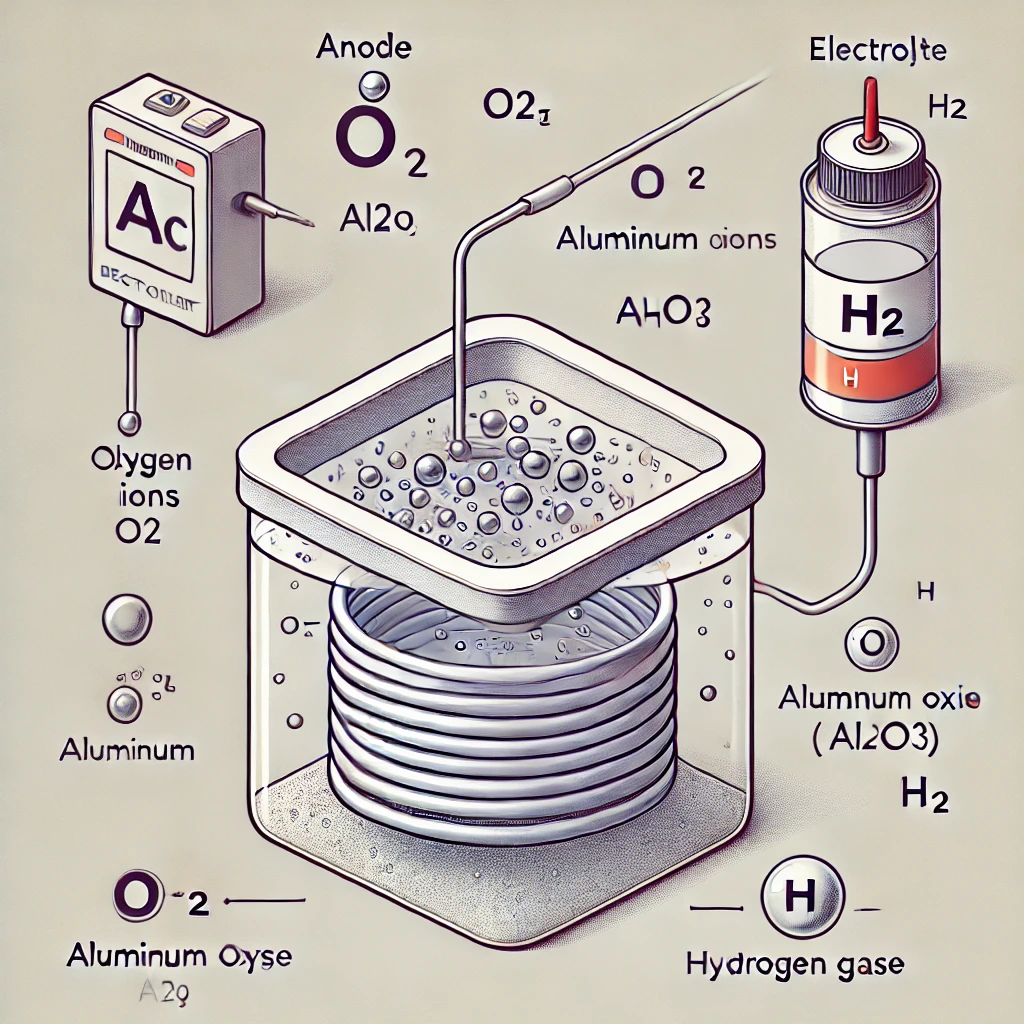

3. Anoodic oxidation

The core reaction occurs in the electrolytic cell and generates a dense oxide film on the aluminum surface through electrochemical action. The specific reactions are shown as follows:

Oxidation process:

When the aluminum coil is connected to the power supply and used as the anode, the water molecules in the electrolyte decompose under the action of the electric current, releasing oxygen ions (O⊃2;). Oxygen ions react with the surface of aluminum to form alumina (Al ₂ O ₃). The chemical reaction formula is: 2Al + 3H2O Al2O3 + 3H22Al + 3H ₂ O Al₂O₃ + 3H ₂ 2Al + 3H2 O Al2O3 + 3H2

Formation of the oxide film:

The resulting oxide film is divided into two layers:

compact layer:

Dense alumina layer close to the aluminum surface has excellent corrosion resistance.

porous layer:

The outer layer is a porous structure to facilitate subsequent staining or sealing processing.

4. Post-treatment process

After anodic oxidation, aluminum rolls usually require further processing to enhance performance:

dye:

Using the adsorption performance of porous layer, the surface of aluminum coil is presented in many colors by electrolytic coloring or dyeing technology.

hole sealing:

The pores in the oxide film are closed by hot water, steam or chemical solution to further improve the corrosion resistance and wear resistance.

5. Quality inspection and arrangement

After anodic oxidation, conduct surface quality and performance testing to ensure that they meet the product requirements. Qualified products will be rolled, packaged and stored for delivery or further processing.

Features of the anodized aluminum oxide rolls

The anodized aluminum coil is a high performance aluminum material after electrochemical treatment and forming a uniform, dense and durable oxide film on its surface. This process gives the aluminum coil many unique properties, making it very popular in all walks of life. The following are the main features of the anodized aluminum oxide rolls:

1. Excellent corrosion resistance

The oxide film formed on the surface of the anodic aluminum oxide coil has high corrosion resistance, and can effectively resist the erosion of the atmosphere, water and chemical substances.

Salt resistance fog corrosion:

Especially suitable for use in coastal areas and in industrial environments.

Persistent protection:

The oxide film does not peel off or fall off, and is firmly combined with the aluminum substrate to provide long-term protection.

2. Enhance the hardness and wear resistance

The surface hardness of the aluminum coil is significantly increased, which can effectively resist mechanical wear and scratches.

Increase in hardness:

The oxide film hardness can reach HV 300, suitable for mechanical parts and high strength application scenarios.

Scratch resistance:

Good appearance and performance in frequent contact or friction.

3. Excellent decorative effect

The anodic aluminum coil surface has a unique metal texture, while supporting a variety of color and texture choices, widely used in the field of decoration.

Natural metallic sheen:

The oxide film has high transparency and can fully show the natural texture of aluminum.

Diversified colors:

Through dyeing technology, black, gold, blue and other colors can be selected to meet the needs of personalized design.

Multiple surface treatments:

Customizable matte, shiny or brushed effects to suit different design styles.

4. Good high-temperature resistance

The anodic oxide film can still maintain stable performance in high temperature environment, which is not easy to soften or deformation.

high temperature stability:

Suitable for industrial furnace, heating equipment and other high temperature occasions.

fire protecting performance:

It shows a good flame retardant effect in building applications and meets the safety standards.

5. Light weight and high strength

The light weight of aluminum itself, coupled with the improvement of surface performance after anodic oxidation treatment, makes the anodized aluminum roll a light and high-strength material.

weight reduction:

Suitable for aerospace and automotive industry, can effectively reduce energy consumption.

High structural strength:

Lightweight and durable, suitable for carrying applications.

6. Superior insulation performance

The anodic oxide film has good electrical insulation performance and is favored in the field of electronic equipment and electrical shell.

high resistance:

Widused in circuit boards and insulating components.

No electromagnetic interference:

It can effectively isolate electromagnetic waves and play a protective role on precision equipment.

7. Environmental protection and sustainability

Anoodized aluminum coil meets the requirements of environmental protection and is a kind of recyclable green material.

Non-toxic:

The oxide film is non-toxic to the human body and the environment.

callable preferred stock:

Anoodized aluminum coil material can be 100% recycled to reduce resource waste.

8. Low maintenance costs

Due to the high durability of the oxide film, the anodic alumina roll requires little additional maintenance.

The surface is easy to clean:

Dirt and dust are easily wiped away and kept smooth and clean.

Strong weather resistance:

No frequent replacement or repair in the outdoor environment, saving maintenance costs.

9. Strong processability

Anoodized aluminum coil not only superior performance, but also has good processing performance, suitable for a variety of manufacturing processes.

Bending, cutting:

Suitable for the fabrication and assembly of complex shapes.

Good coating adhesion:

The surface of the oxide film can be further sprayed or bonded to improve the application flexibility.

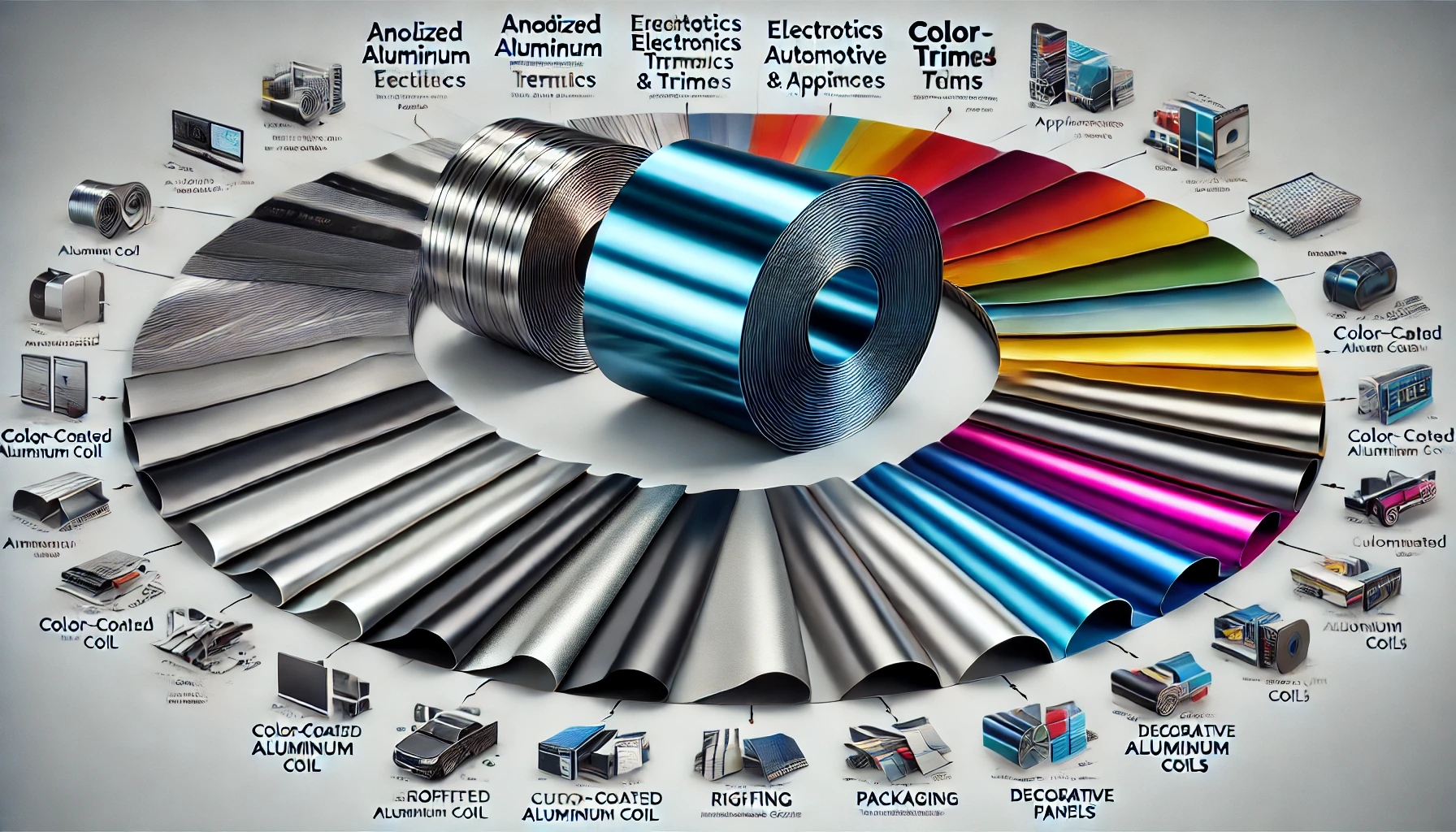

10. Wide range of applications

With the above characteristics, anodized aluminum rolls are widely used in the following fields:

architectural ornament:

Curtain wall, ceiling, door and window frame, etc.

electric products:

Cell phone case, laptop computer case, etc.

traffic:

Auto parts, high-speed rail interior panels, aviation equipment, etc.

Fitting:

Light and lanterns, kitchenware, furniture finishes, etc.

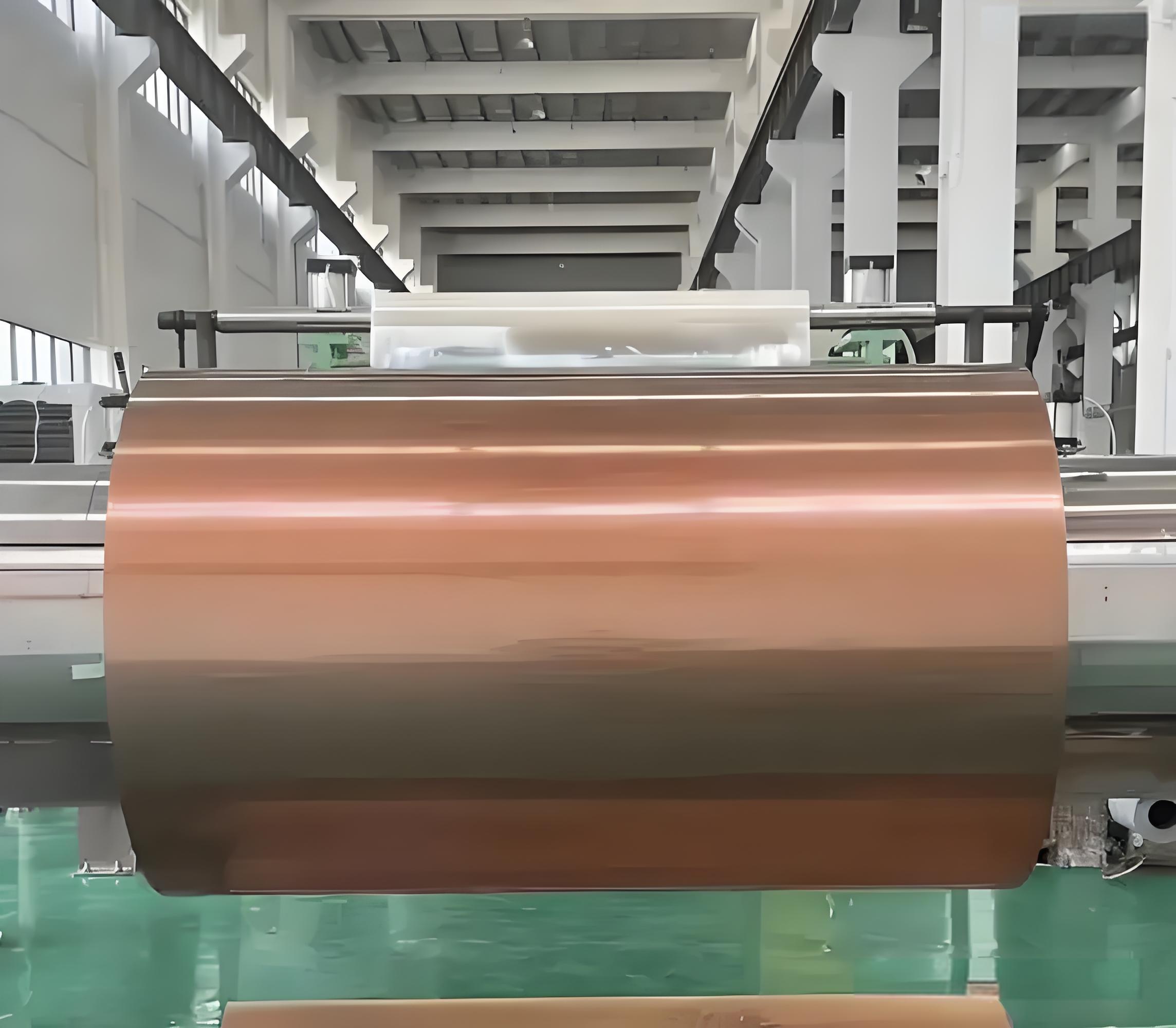

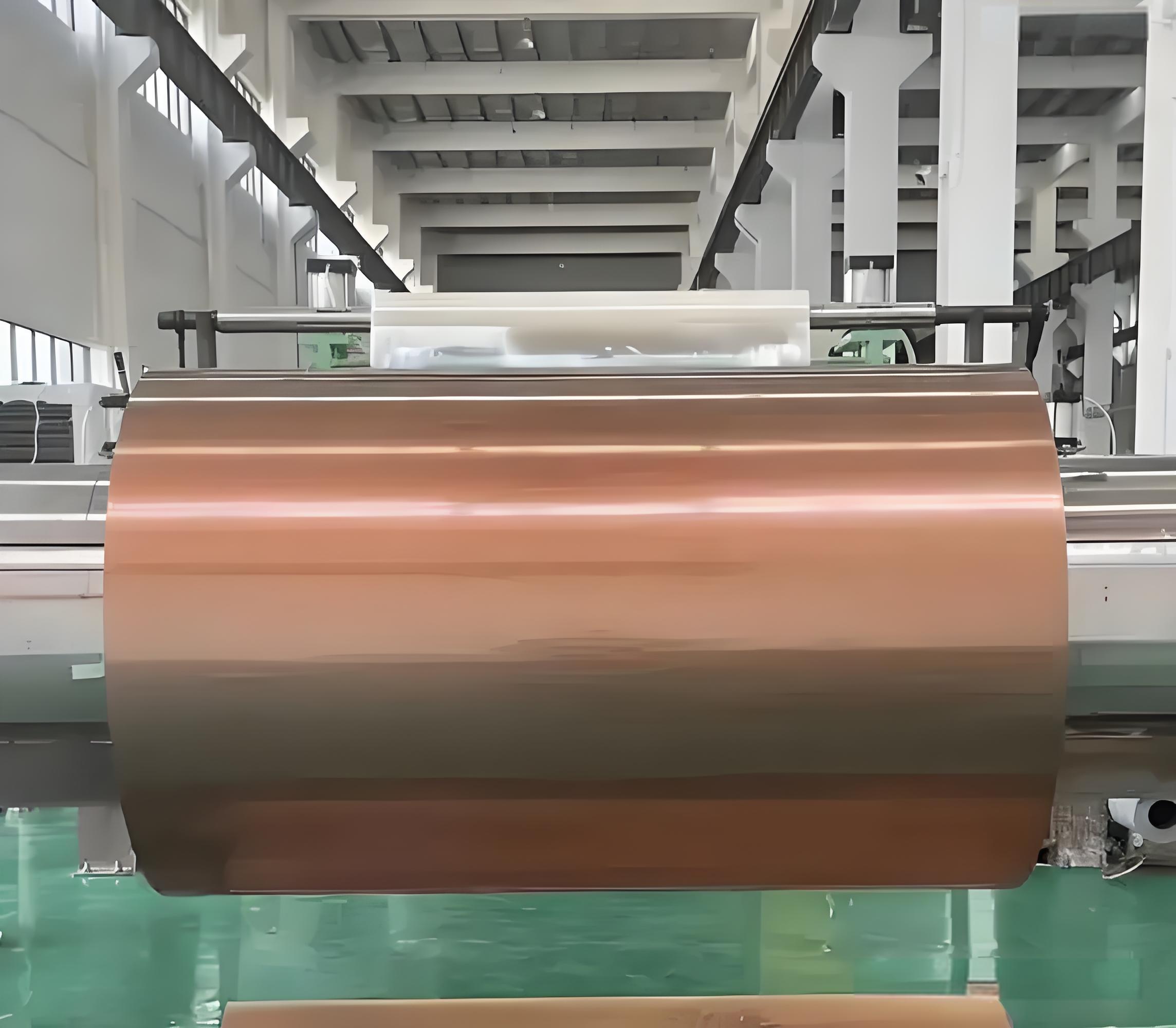

What is a precoated aluminum roll?

Production process for pre-coated aluminum rolls

Precoated aluminum roll (also known as color coated aluminum roll) is a material coated with functional or decorative coating on the surface of the aluminum roll, with excellent weather resistance, decoration and workability. Its production process is completed through a series of precision machining steps to ensure the uniformity and durability of the coating. The following is the detailed manufacturing process for the precoated aluminum rolls:

1. Aluminum substrate preparation

The first step in the production of precoated aluminum rolls is to prepare the aluminum substrate to ensure the adhesion and coating quality of the subsequent coatings.

cleaning:

Use a chemical detergent to remove oils, oxides and impurities from the aluminum roll surface.

Make sure the aluminum roll surface is completely clean without any residue.

Repair edge processing:

Cut the aluminum roll to ensure uniform width, remove burrs and improve the machining accuracy.

2. Surface treatment

In order to enhance the adhesion of the coating and improve the corrosion resistance of the aluminum coil, the surface chemical or mechanical treatment of the aluminum substrate is required.

chemical pretreatment:

scouring:

Remove the surface oxide layer and increase the activity of the aluminum coil surface.

Phosphorylation or Chromium:

A protective film is formed on the aluminum surface to provide a better attachment base for the coating.

Mechanical treatment:

Wire processing:

Mechanically, you can form a fine texture on the surface of the aluminum coil to increase the decorative effect.

polishing:

Enhance surface smoothness and smoothness to provide ideal surface conditions for coating.

3. Coating preparation

Coating is the key of precoated aluminum roll, and its type and formulation depend on the use and performance requirements. Common coatings include:

Polyester (PE) coating:

Suitable for interior decoration, with excellent flexibility and impact resistance.

Polyvinylidene fluoride (PVDF) coating:

Excellent weather resistance and UV resistance, suitable for outdoor use.

epoxy coating:

Strong chemical resistance, used for special industrial use.

After the coating is prepared, the coating is filtered and stirred and free of particles or impurities.

4. Coating process

The coating process is completed by a high-precision roller coating machine to ensure that the coating is evenly coated on the aluminum roll surface.

primary coat:

Apply a layer of primer to enhance the adhesion between the coating and the aluminum substrate, and to prevent corrosion.

The bottom coating thickness shall be strictly controlled to ensure the overall performance of the coating.

topcoat:

Apply functional or decorative finish to meet different needs through various colors and effects.

The coating thickness should be accurately controlled during the rolling coating process to ensure the uniformity and stability.

Back to paint:

A protective coating on the back of the aluminum roll provides additional protection and enhanced durability.

5. Dry and solidify

After coating, the aluminum coil is sent to a high temperature drying oven for curing of the coating.

High temperature drying:

The temperature is usually controlled between 180°C and 250°C, and the curing temperature and time are adjusted according to the coating type.

After drying, the coating is hardened, and the surface is smooth and firm.

Multiple drying:

If multiple layers are required, repeat the coating and drying steps until the final effect is achieved.

6. Cooling treatment

The cured aluminum rolls need to be cooled quickly to shape and keep the coating stable.

air cooling:

Use cold air to purge the surface of the aluminum coil to accelerate the cooling process.

water cooling:

For some high-temperature coatings, water cooling is more efficient.

7. Surface detection

During the production process, the coating quality is strictly tested to ensure that the products meet the requirements.

inspection of appearance:

Check whether the coating is smooth, with color difference, bubbles or pinholes.

Performance detection:

Coating adhesion test: secure the coating bond to the substrate.

Corrosion resistance test: simulate the corrosion resistance of salt spray or damp heat environment.

Weather resistance test: Test the durability of the coating by the changes in light and temperature and humidity.

8. Winding and packaging

Qualified precoated aluminum rolls are rolled and packaged.

wind:

Use special equipment to ensure no wrinkles or damage.

pack:

Special packaging materials of moisture-proof and scratch-proof shall be used for easy transportation and storage.

Features of a precoated aluminum roll

Precoated aluminum coil (also known as color-coated aluminum coil) is a high-performance material coated with organic coating on the surface of aluminum substrate, which is favored because of its excellent properties and diversified applications. The following are the main features of the precoated aluminum roll:

1. Excellent weather tolerance

Pre-coated aluminum roll surface coating after special treatment, with strong ultraviolet resistance and weather resistance.

Strong UV resistance:

Long-term exposure to sunlight is not easy to fade or aging, especially suitable for outdoor use.

Climate resistance:

It can maintain the stable performance under the extreme high temperature or low temperature conditions.

2. Excellent corrosion resistance

The coating effectively protects the aluminum substrate from the chemicals and moisture present in the environment.

Anti-salt fog corrosion:

Suitable for coastal areas and high humidity environment.

Acid and alkali resistance:

Good performance can also be maintained in the industrial environment.

3. Beautiful and diverse decorative effects

Pre-coated aluminum rolls offer a rich selection of colors and patterns to meet personalized needs.

A variety of colors:

Can provide red, blue, gold, silver and other colors, and even special metallic luster.

Diversified textures:

Including wood grain, stone grain, wire drawing effect, etc., is widely used in building and home decoration.

homogeneous coating:

The coating is smooth and smooth, the color consistency is strong, and the overall decoration effect is superior.

4. Good processing performance

Precoated aluminum rolls can maintain the integrity of the coating and are suitable for a variety of processing methods.

Bending, stamping:

The coating shall not crack and fall off during the processing process.

Easy to cut and bend:

Suitable for complex shapes and custom design requirements.

5. High temperature resistance and flame retardant resistance

The high temperature stability and flame retardant properties of the precoated aluminum roll coating make it the first choice for safe materials.

thermostability:

Can maintain the physical performance and color stability under high temperature conditions.

Flame resistance:

Meet the fireproof building material standards, enhance safety.

6. Lightweight characteristics

Pre-coated aluminum coil inherits the advantages of light aluminum texture, and also has high strength.

in light weight:

Easy transportation and construction, reduce the overall load of construction or equipment.

High strength:

Ensure excellent structural strength while reducing the weight.

7. Easy tainability

The surface coating has good stain resistance makes the precoated aluminum roll very easy to clean and maintain.

Strong anti-pollution ability:

The surface is not prone to dust and oil pollution.

Low maintenance cost:

Keep a shiny and clean look.

8. Environmental protection and sustainability

Precoated aluminum roll is an environmentally friendly material that meets green standards during production and use.

Non-toxic:

The coating is environmentally friendly and harmless to the environment and the human body.

retrievability:

Aluminum material and its coatings can be 100% recycled to reduce the waste of resources.

9. Long service life

High-quality coating process greatly improves the durability of the pre-coated aluminum coil.

Up to over 20 years of service life:

Also maintain good performance in outdoor environments.

Easy to crack or peeling:

The coating is stable for the long term even under harsh conditions.

10. A wide range of applications

Due to their versatility and superior performance, pre-coated aluminum rolls are widely used in many industries and fields.

Construction field:

Curtain wall, roof, ceiling, door and window decoration, etc.

domestic appliance:

Refrigerator panels, microwave oven casing, etc.

traffic:

Car interior panels, body shell and other lightweight parts.

Industrial use:

Equipment shell, protective cover, etc.

11. High cost performance

Compared with other similar materials, pre-coated aluminum rolls achieve a good balance between performance, appearance and cost.

economical and practical:

Mass production and ease of processing reduce overall costs.

Excellent performance:

Provide superior durability and decoration effects at a lower cost.

Price difference analysis

1. Raw material cost analysis

Anodic alumina roll

main raw material:

High purity aluminum substrate (usually use AA1050, AA1060 and other high purity aluminum alloy).

Chemical solution (such as sulfuric acid, phosphoric acid and other electrolyte, used for oxidation treatment).

Other auxiliary materials (such as dyes, dyes, sealants).

Cost features:

Aluminum substrate accounts for 70% -80% of the total cost, which is the most important cost source of anodized aluminum coil.

The consumption of chemical reagents is large, but the unit price is relatively low, accounting for 10% -15% of the total cost.

The consumption of auxiliary materials varies slightly depending on the color and use of the product.

Pre-coated aluminum roll

main raw material:

Aluminum substrate (usually using high strength aluminum alloy such as AA3003, AA3105).

Coatings (such as polyester, fluorocarbon and other functional coating materials).

Chemical pretreatment agents (for cleaning and surface treatment).

Cost features:

The cost of aluminum substrate accounts for 60% -70%, slightly lower than the anodized aluminum coil.

Coating cost is high, especially the fluorocarbon coating, the price is as high as 30,000-50,000 yuan per ton, accounting for about 20% -25% of the total cost.

Pretreatment agents and other auxiliary materials are less cost, accounting for about 5% -10%.

2. Production cost analysis

Anodic alumina roll

· Production process consumption:

o power consumption:

§ The anodic oxidation process requires a long time of electrolysis operation, and the power cost accounts for 30% -40% of the total production cost.

o Water consumption:

§ The water consumption is large during cleaning and oxidation, and the water treatment cost is higher.

o time cost:

§ A single oxidation treatment takes a long time (usually several hours), resulting in low production efficiency.

· Equipment and labor:

o Equipment maintenance costs are high, such as the oxidation tank and the electrolysis equipment.

o The technical requirements for the operators are higher, and the labor cost is slightly higher.

Pre-coated aluminum roll

· Production process consumption:

o Coating process:

§ The roller coating process, the coating use high accuracy, less waste, relatively reduce the unit production cost.

§ The drying and curing stage requires high temperature drying, and high electricity and fuel costs.

o production efficiency:

§ The precoated aluminum roll has short production cycle, high yield of single batch and higher efficiency than anodized aluminum coil.

· Equipment and labor:

o The cost of coating equipment (such as roller coating machine and drying furnace) is high, but the maintenance cost is lower than that of anodizing equipment.

o High degree of process automation, and the labor cost is relatively low.

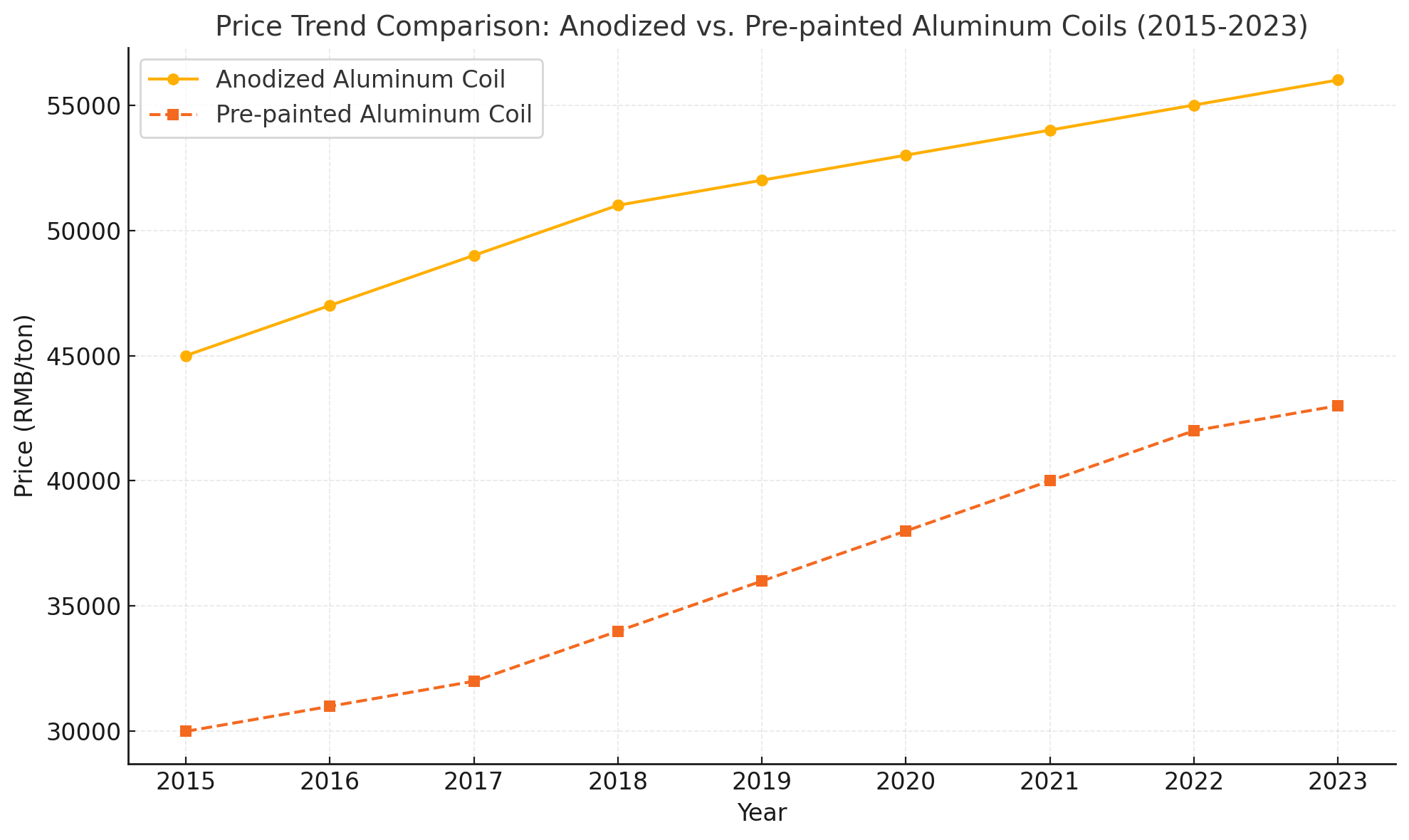

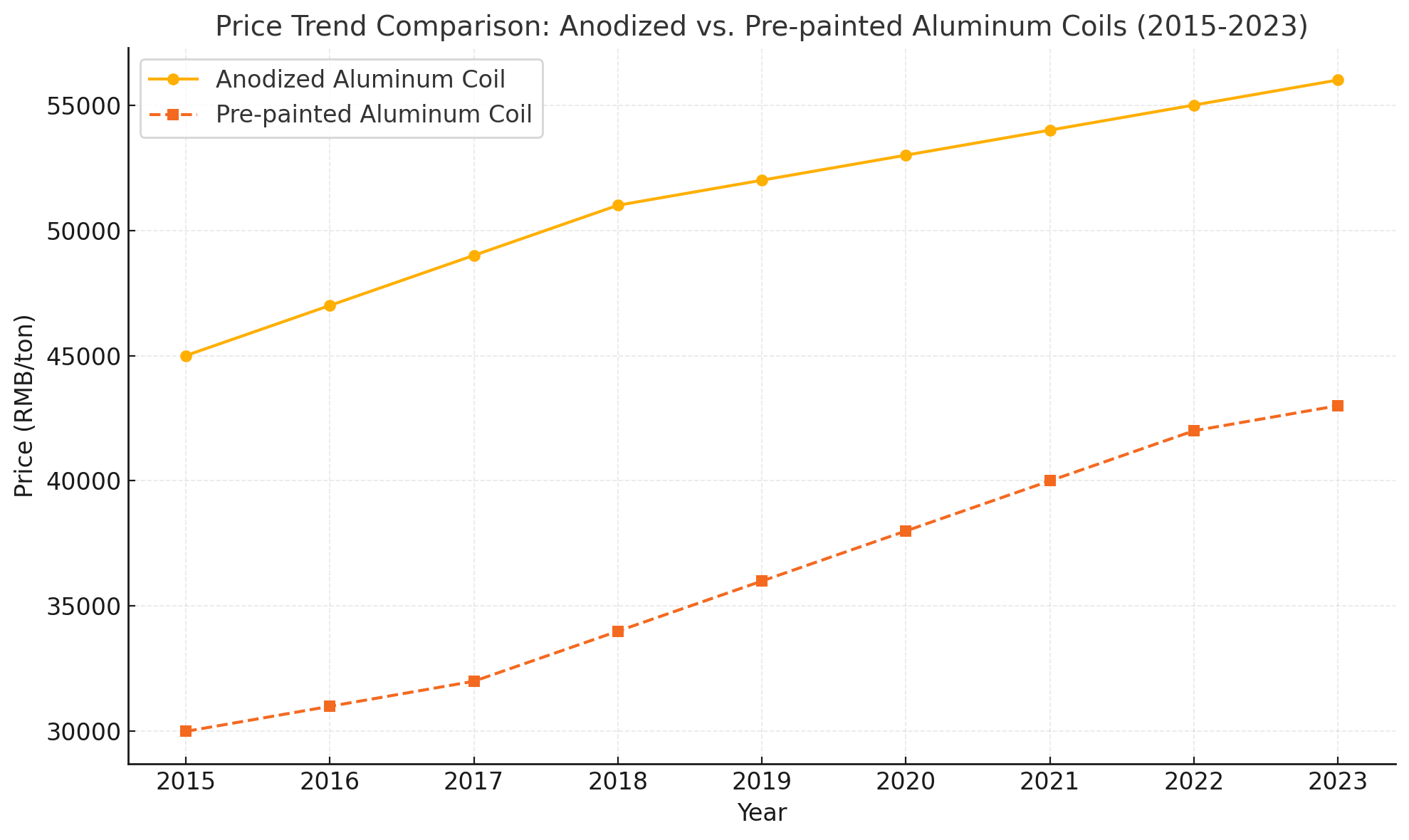

3. Market pricing analysis

Anodic alumina roll

· market price:

o According to the thickness of the aluminum substrate and the complexity of the surface treatment process, the market price of the anodized aluminum coil is usually 40,000 to 100,000 yuan per ton.

· influencing factor:

o Fluctuations of raw materials:

The fluctuation of aluminum price directly affects the product cost and pricing.

o Process complexity:

The richer the color, the more special the decorative effect of the aluminum roll, the higher the price.

o market demand:

Mainly used in the high-end decoration field, such as electronic products shell, building interior decoration, the demand is relatively stable.

Pre-coated aluminum roll

· market price:

o Differences in coating types cause significant price differences:

§ Ordinary polyester coated aluminum coil is 30,000-40,000 yuan per ton.

§ High-end fluorocarbon-coated aluminum coil of 50,000-60,000 yuan per ton.

· influencing factor:

o Pating type and thickness:

Forocarbon coating is expensive because of its superior performance.

o Color and decorative effects:

Special-textured or custom-designed aluminum rolls cost more.

o Field of use:

Building curtain wall and high-end home appliances field demand, the price is higher than ordinary industrial use.

4. Comprehensive comparison

Cost / price dimension | Anodic alumina roll | Pre-coated aluminum roll |

Raw material cost | High-purity aluminum substrates cost even higher | Aluminum substrate cost is slightly lower, and the coating cost is high |

cost of production | Electricity and water resources have long consumption, and longer cycles | High degree of automation and lower unit production costs |

market price | Lower price per ton (40,000-100,000 yuan) | Higher price per ton (30,000-60,000 yuan) |

application area | High-end decoration and functional areas, such as electronic product cases | Widely used in building curtain walls, home appliances and industrial decoration |

5. Development prospect analysis

Anodic alumina roll

· superiority:

Unique metal texture and excellent corrosion resistance in high-end applications are irreplaceable.

· inferior strength or position:

With a long production cycle, high energy consumption, and a weak competitiveness in large-scale industrial applications.

· market swing:

In the future, it will prefer small-batch and high value-added products, such as consumer electronics and aerospace.

Pre-coated aluminum roll

· superiority:

High production efficiency and diverse decorative effects, it can meet the diversified needs of the construction and industrial fields.

· inferior strength or position:

For the high-end market, the coating stability and environmental performance still need to be improved.

· market swing:

With the growth of green building materials and customized demand, the share of precoated aluminum rolls in the high-end market will continue to increase.

Use comparison

1. Field of architectural decoration

Anodic alumina roll

· Use features:

o Mainly used for the interior and exterior decoration of high-end buildings, such as curtain wall, doors and Windows, and ceiling.

o The anodized surface has a metallic luster and showing a unique high-end texture, especially suitable for the decoration of luxury buildings or landmark buildings.

o Superior corrosion resistance, especially well in wet or salt spray environments (such as coastal areas).

· typical case:

o High-end commercial buildings, luxury hotel lobby interior decoration.

o A building facade with a sense of design.

Pre-coated aluminum roll

· Use features:

o Often used in the building exterior wall, roof, canopy, rolling curtain door, etc., more inclined to large area decoration needs.

o The coated surface provides rich color choices and texture effects, such as wood and stone patterns, etc., to meet the diverse design needs of modern architecture.

o Weather resistance and UV resistance make it more economical and practical to use outdoors.

· typical case:

o Color room panel.

o Exterior wall of commercial building, roof of factory building.

2. Home appliance industry

Anodic alumina roll

· Use features:

o Shell and decorative panels that are mostly used for high-end home appliances, such as refrigerators, washing machines, ovens, etc.

o Smooth surface and wear-resistant, suitable for frequent touch of home appliances products.

o The metal texture enhances the high-end positioning of the product, and complements the modern and simple design style.

· typical case:

o The control panel for high-end refrigerators and washing machines.

o The shell of small home appliances (such as coffee machine, juicer).

Pre-coated aluminum roll

· Use features:

o Applied to the external cover of ordinary household appliances, especially refrigerators, microwave oven, air conditioning shell.

o The coating can provide different colors and textures according to the demand, suitable for the diversified design of home appliances.

o Cost-effective, suitable for mass production of home appliances products.

· typical case:

o Fridge side panels and color panels.

o Air conditioning shell.

3. Electronics industry

Anodic alumina roll

· Use features:

o It is widely used in the field of consumer electronics, such as laptops, mobile phone cases, etc.

o After anodizing treatment, the surface of aluminum coil is strong and durable, and has metallic luster, adding advanced sense to electronic products.

o The antioxidant and scratch-resistant characteristics make it very suitable for the electronic equipment that need to maintain the appearance quality for a long time.

· typical case:

o Laptop shell.

o Smart phone backplane.

Pre-coated aluminum roll

· Use features:

o In less used in electronic products, mainly for decorative and durability requirements are not high parts, such as internal parts or low-end equipment shell.

o The color flexibility of the coating can be used in equipment design in special scenarios, but the overall application scope is small.

· typical case:

o External packaging parts of ordinary electronic devices.

4. Transportation industry

Anodic alumina roll

· Use features:

o Decoration and functional components for high-end vehicles, such as automotive interiors, rail transit decorative panels.

o High strength and corrosion resistance, suitable for harsh use environment.

o The unique metal texture enhances the grade of the product and is widely used in the aerospace field.

· typical case:

o Car interior trim pieces.

o Aircraft cockpit interior trim panel.

Pre-coated aluminum roll

· Use features:

o Applied to cover the needs of transport, such as truck cars, container shell.

o The coating provides good protection and decorative effects, suitable for durability and cost-sensitive areas.

· typical case:

o Container shell.

o Bus or van exterior cover parts.

5. Industrial use

Anodic alumina roll

· Use features:

o It is mainly used in the industrial equipment shell and guide rail with high surface quality and durability requirements.

o Excellent corrosion resistance, can be used in high humidity, high pH environment.

· typical case:

o Medical equipment enclosure.

o Surface components of chemical equipment.

Pre-coated aluminum roll

· Use features:

o Protective shell and decorative parts used for ordinary industrial equipment.

o The coating can effectively resist dust, moisture and chemical erosion, and extend the service life of the equipment.

· typical case:

o Industrial equipment enclosure.

o Production line protective panel.

6. Packaging field

Anodic alumina roll

· Use features:

o For high-end gift packaging, cosmetic shell and other packaging materials that need high texture and beauty.

o Good scratch resistance, ensuring that the product is not easy to damage the appearance during transportation and use.

· typical case:

o High-end cosmetics packaging box.

o Gift decorating panel.

Pre-coated aluminum roll

· Use features:

o Applied in mass production of ordinary packaging materials, more consideration of cost and practicality.

o Provide a variety of color choices, suitable for different brand packaging needs.

· typical case:

o food container.

o Commercial advertising packaging panel.

7. Comprehensive comparison

The purpose of the field | Anodic alumina roll | Pre-coated aluminum roll |

architectural ornament | High-end interior and exterior decoration, strong metal texture, superior corrosion resistance | Exterior wall, roof, color design, cost-effective |

Home appliance industry | High-end home appliance shell, excellent surface wear resistance and texture | Ordinary home appliance shell, high color and texture flexibility |

electron industry | Consumer electronics high-end shell, antioxidant and durable | Internal parts or low-end equipment, decorative in general |

traffic | High-end automotive and aviation areas, decoration and function combined | Large area coverage, practicality and cost first |

Industrial use | Corrosion-resistant industrial equipment enclosure | Protection and trim housing to meet the cost requirements |

Packaging field | High-end gifts, cosmetics and packaging | General food and commercial packaging, focus on mass production |

Comparison of service life

1. Comparison of corrosion resistance

Anodic alumina roll

· characteristic:

o Anodized oxide layer is a dense alumina protective layer, its corrosion resistance is very excellent, can effectively resist the erosion of moisture, acid or alkaline environment.

o In coastal areas and serious industrial pollution, anodic aluminum coil performance is particularly excellent, which can maintain more than 20 years without obvious corrosion.

· superiority:

o No additional coating, natural long-term corrosion resistance.

Pre-coated aluminum roll

· characteristic:

o The quality of the coating material directly determines its corrosion resistance. High-end coating (such as PVDF) can provide the corrosion resistance near the anodic aluminum oxide coil, but the ordinary coating (such as PE) is easy to fail in the environment with high humidity.

o In harsh environments, the coating may take 5-10 years to maintain protective performance.

· superiority:

o Suitable for use in moderately corrosive environments, but requiring regular inspection and maintenance.

2. Comparison of weather tolerance

Anodic alumina roll

· characteristic:

o The anodic oxide layer has extremely strong UV resistance and does not fade or age due to prolonged exposure to sunlight.

o In the extreme temperature difference environment, the surface stability is high, not easy to appear cracking or peeling phenomenon.

· Typical life:

o In outdoor environments, anodized aluminum rolls can have a life span of more than 30 years, requiring almost no additional maintenance.

Pre-coated aluminum roll

· characteristic:

o The weather resistance of coating varies from type to type. PVDF coating has strong UV resistance and a life span of up to 20-25 years, while ordinary PE coating has a general weather resistance with a life span of between 10-15 years.

o Chronic exposure to sunlight may cause fading or pulverization of the coating and require regular recoating.

· Typical life:

o In an outdoor environment, its life span is between 10 and 25 years, depending on the coating quality, and the coating needs to be regularly refurbished, to maintain aesthetic and protective performance.

3. Compare the maintenance requirements

Anodic alumina roll

· Maintenance frequency:

o Basically maintenance free, only regular cleaning of surface dust.

· Maintenance cost:

o Due to the extremely high durability of the oxide layer, no additional maintenance costs are usually required.

Pre-coated aluminum roll

· Maintenance frequency:

o Depending on the coating quality and environment, usually coating or repair every 5-10 years.

· Maintenance cost:

o Some maintenance costs, including coating repair, respraying, etc., especially in harsh environments, maintenance costs will increase significantly.

4. Comparison of aging performance

Anodic alumina roll

· expression:

o The aging process of anodic aluminum oxide coil is extremely slow, and the surface gloss may be slightly reduced after long-term use, but there will not be problems such as flaking and cracking.

o In severe industrial pollution or high salt environment, the service life remains stable.

Pre-coated aluminum roll

· expression:

o Coating aging shows fading, pulverizing and even peeling, especially when ordinary coating is poor in long-term exposure to ultraviolet light and contaminants.

o The coating material needs to be updated regularly to delay the aging process.

5. Comprehensive comparison of service life

characteristic | Anodic alumina roll | Pre-coated aluminum roll |

Corrosion resistance | Excellent (no obvious corrosion over 20 years) | By coating quality, PVDF is excellent and PE is poor |

weather fastness | Excellent, more than 30 years without fading | PVDF 20-25 years, and PE 10-15 years |

Maintain demand | Low, basically maintenance-free | Regular recoating or repair |

Aging performance | Slow aging, and surface stability | The coating is aging quickly, requiring maintaining and life extension |

Typical service life (outdoor) | More than 30 years | 10-25 Years |

Market demand and trend analysis

1. Market demand analysis

Anodic alumina roll

· characteristics of demand:

o High-end market dominance:

Anoodized aluminum rolls are in high demand in high-end building decoration, electronic equipment shell and the aviation industry for their excellent corrosion resistance and high-end appearance.

o Customization requirements:

Customer demand for oxide film thickness, surface color, and texture drives the development of customized products.

o Green and environmental protection requirements:

Because the anodic oxidation process is relatively environmentally friendly, in line with the trend of sustainable development, in the background of environmental awareness, the market demand shows an increasing trend.

Pre-coated aluminum roll

· characteristics of demand:

o Middle-and low-end market mainly:

Pre-coated aluminum rolls are widely used in the middle and low-end building decoration and home appliance manufacturing because of their relatively low cost and rich color and surface design.

o Rapid replacement of traditional materials:

In the case of increasing market demand for lightweight and aesthetics, precoated aluminum coil gradually replace traditional steel, wood and so on, and become one of the mainstream materials.

o Prefabricated buildings drive demand:

With the development of prefabricated buildings, the standardized production and easy processing characteristics of precoated aluminum rolls are favored.

2. Main application areas and growth potential

Anodic alumina roll

· High-end construction field:

Such as curtain wall, roof and high-end decorative panels, the market demand is growing steadily, especially in luxury buildings and landmark buildings.

· Consumer electronics sector:

It is widely used in high-end products such as laptops, mobile phone cases and tablets, and technological innovation drives demand growth.

· Air and rail transit:

Due to its lightweight and high-strength characteristics, it is widely used in aerospace and high-speed train body materials, and the future demand will continue to grow as the transportation industry expands.

Pre-coated aluminum roll

· Civil construction field:

Widely used in the roof, wall, ceiling, etc., especially in the economic housing market with strong demand.

· Home appliance field:

Refrigerators, air conditioners and other home appliances shell a large number of precoated aluminum rolls, with its beauty and cost advantages to occupy the market share.

· Advertising and signage field:

Due to its rich color choice and easy to process, pre-coated aluminum rolls have great market potential in billboard production.

3. Technology development trend

Anodic alumina roll

· process optimization:

o New electrolyte and energy-saving anodized oxidation process are gradually adopted to further reduce production energy consumption and cost.

o The development of enhanced anodized technologies, such as hard oxidation and color oxidation, to meet the needs of more high-end applications.

· product innovation:

o Larger size and more complex shape of anodized aluminum coil product development to meet the needs of large construction and industrial applications.

o Surface treatment technology combined with intelligent functions (such as electrical conductivity and antibacterial properties) has become a new growth point.

Pre-coated aluminum roll

· Coating technology upgrade:

o High-performance coatings (such as PVDF, nano-coating) to further improve weather resistance and corrosion resistance, and open up new space for the middle and high-end market.

o The development and application of environmental coatings in response to green building and environmental regulations.

· Digital production:

o The introduction of intelligent manufacturing technology to realize the rapid customized production of color and pattern to meet the diversified market demand.

o High-speed automatic coating process improves production efficiency and reduces labor costs.

4. Market outlook forecast

Anodic alumina roll

· steady-state growth:

o With the increasing demand of the high-end market and the development of green buildings and high-tech products, the market size of anodized aluminum rolls is expected to rise steadily at a compound growth rate of 6% -8% per year.

· geographical distribution:

o Asian markets (especially China and India) will be the main growth force, with demand for high-end products stable in Europe and Europe.

· challenge and opportunity:

o Challenge: The anodization process has a high resource consumption and requires further optimization of the production process.

o Opportunities: Intelligent manufacturing and the development of functional aluminum materials inject new impetus into the market.

Pre-coated aluminum roll

· Rapid expansion:

o The pre-coated aluminum coil market is expected to expand rapidly at a compound annual growth rate of 8-10%, especially driven by prefabricated buildings and lightweight trends.

· eographical distribution:

o The Chinese market demand is the largest, the demand in Southeast Asia and Africa market is growing rapidly, and the European and American markets are becoming stable.

· challenge and opportunity:

o Challenge: the market competition is fierce, and the profit margin of low-end products is narrowed.

o Opportunities: High-end coating technology and environmental protection product development bring new demand.

5. Comparison of the overall development trend

characteristic | Anodic alumina roll | Pre-coated aluminum roll |

market positioning | High-end market is the main | The middle and low-end markets took the lead, and the high-end market gradually expanded |

Growth momentum | Demand for high-tech products, green building trend | Prefabricated buildings, home appliance industry demand-driven |

Technology upgrade direction | Hard quality oxidation, intelligent function development | Environmental protection coating, high-performance coating development |

market prospect | Steady growth, the size of the market stable expansion | Rapid expansion, and gradually cover more application areas |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg