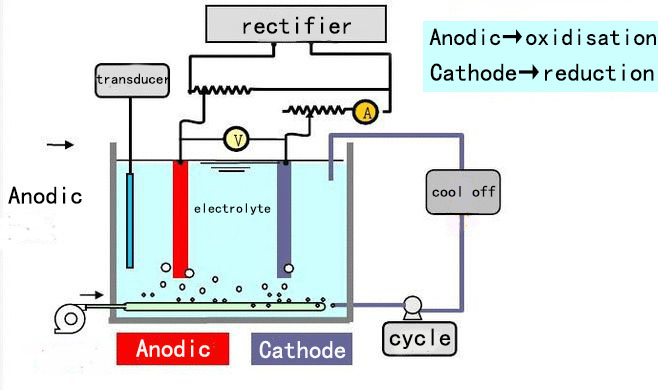

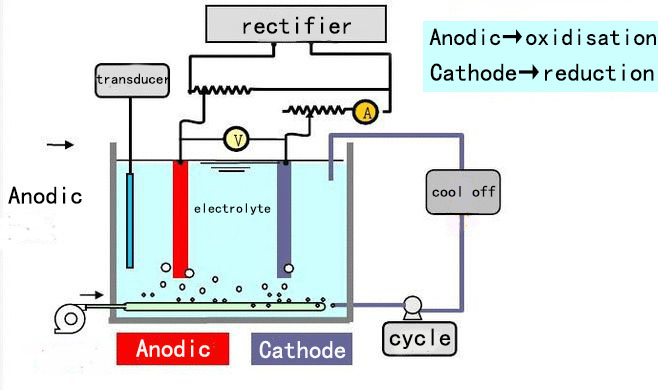

Anodic oxidation process

Anodic oxidation process is a surface treatment technology that forms an oxide film on the metal surface through electrolysis reaction. The process of using aluminium or aluminium alloy products as anode, placing them in electrolyte solution for electrification, and using electrolysis to form aluminium oxide film on their surfaces is called anodic oxidation treatment of aluminium and aluminium alloy.

The main steps of the anodising process include:

1. Surface pretreatment: chemical or physical methods of cleaning the surface of the profile, bare pure substrate, in order to facilitate the acquisition of complete, dense artificial oxide film. It is also possible to obtain a mirror or non-glossy (matt) surface by mechanical means.

2. Anodic oxidation: After surface pretreatment of the profile, under certain process conditions, the substrate surface anodic oxidation occurs, generating a layer of dense, porous, strong adsorption Al₂O₃ film layer.

3. Sealing pore: Use HT800 high temperature sealing agent, etc. to close the membrane pore pores of the porous oxide film generated after anodic oxidation, so that the oxide film can prevent contamination, corrosion resistance and wear-resistant performance enhancement.

Through the anodic oxidation process, the metal surface can obtain the following characteristics:

1. Increase corrosion resistance: the oxide film can protect the metal surface from corrosion.

2. Increased hardness and wear resistance: the oxide film has high hardness and wear resistance.

3. Improve decorative properties: it can be used to make the metal surface show various colours and luster through colouring and other methods.

4. Improvement of insulating properties: The oxide film has good insulating properties.

5. Enhancement of adsorption capacity: the porous structure of the oxide film gives it a strong adsorption capacity.

Anodic oxidation process is widely used in the surface treatment of non-ferrous metals and their alloys such as aluminium, magnesium, etc. It can be used in aerospace, automotive, construction, electronics and other field

The anodising process has the following advantages over other surface treatment processes:

Excellent protective properties

- Corrosion resistance:

Anodic oxidation will form a hard, dense and chemically stable aluminium oxide film on the metal surface, which can effectively isolate the metal from corrosive substances such as air, moisture and salt in the external environment, greatly improving the corrosion resistance of the metal and prolonging its service life. For example, in the aluminium curtain walls of outdoor buildings, the anodized aluminium panels are able to resist the erosion of acid rain, wind and sand and other natural factors, and maintain good appearance and structural performance for a long time.

- Wear-resistant:

The high hardness of the anodic oxide film makes the metal surface have good wear resistance, and can withstand a certain degree of friction and scratching without being easily damaged. Like some aluminium products that often contact with human skin or other objects, such as mobile phone shells, door handles, etc., after anodic oxidation treatment, the surface is not easy to appear scratches, and maintains a better appearance integrity.

Highly decorative

- Multiple colours can be achieved:

Anodic oxide film has a porous structure, which can be used to obtain a variety of bright and long-lasting colours through electrolytic colouring and dyeing to meet different decorative needs, and the colours are uniform, firm and not easy to fade. For example, in the field of electronic products, the anodic oxidation process can be used to give fashionable colours to the aluminium casing, enhancing the aesthetics and personalization of the products.

- Can present different texture:

By adjusting the process parameters, the anodic oxidation film can present different surface texture, such as matte, glossy, satin, etc., which can provide more choice space for the product design and increase the product's sense of hierarchy and texture.

Good insulation performance

Anodic oxidation film has high electrical resistivity, can play a good role in electrical insulation, can be used in the insulation requirements of electronic components, electrical equipment and other products, to prevent current leakage and short-circuit and other problems, to improve the safety and reliability of the product.

Strong bonding with coating

After anodic oxidation treatment of the metal surface, its microstructure becomes rougher, forming many tiny pores and uneven surface, which provides a good adhesion basis for the subsequent coating, and significantly improves the bonding force between the coating and the metal substrate, making the coating more solid and less likely to fall off, and further enhances the protective and decorative effect.

Relatively good environmental performance

Anodic oxidation process generally does not involve the use of heavy metals, toxic and hazardous substances, compared with some traditional surface treatment processes, such as chrome plating, cadmium plating, etc., less harmful to the environment and human health, more in line with modern environmental protection requirements.

High process stability

The anodic oxidation process is relatively mature, through precise control of electrolyte composition, current density, oxidation time and other process parameters, you can obtain a stable and consistent quality of the oxide film, to ensure the stability of the product's performance and appearance, suitable for large-scale industrial production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

Ελληνικά

Suomi

Latine

Dansk

Shqip

Hrvatski

Afrikaans

Gaeilge

Eesti keel

latviešu

Azərbaycan dili

Беларуская мова

ქართული

íslenska

Kinyarwanda

Lietuvių

Lëtzebuergesch

Македонски

Malti

Türkmençe

ئۇيغۇرچە

Cymraeg